South America Hot Sale R101 R72 Metal Roofing Sheet Roll Forming Machine

What is R101 Roof Sheet?

The R101 roof sheet is a type of metal roofing profile commonly used in residential, commercial, and industrial roofing and wall cladding applications. The “R” in R101 often denotes "Ribbed", and 101 usually refers to the effective coverage width of the sheet, typically 1010mm (or 1.01 meters).

This profile features trapezoidal ribs with alternating flat pans and raised sections, providing structural strength, weather

resistance, and an aesthetically pleasing appearance.

----------------------------------------------------------------------------------------------------------------------------------

Key Features of R101 Roof Sheet:

* Effective Width: 1010mm (commonly)

* Rib Height: Generally around 28mm to 32mm

* Pitch (rib spacing): Approx. 203mm between ribs

* Thickness: Usually available in 0.3mm to 0.7mm, depending on application

* Material Options: * Galvanized steel (GI)

* Galvalume (GL)

* Pre-painted galvanized steel (PPGI)

* Aluminum

----------------------------------------------------------------------------------------------------------------------------------

Advantages of R101 Roofing Sheet:

1. High Strength-to-Weight Ratio: Provides excellent structural strength while being lightweight.

2. Easy Installation: Long spans and wide coverage reduce overlaps and installation time.

3. Cost-Effective: Low maintenance, durable, and long-lasting.

4. Versatility: Suitable for roofing, wall cladding, fencing, and even ceiling applications.

5. Corrosion Resistance: Especially when made with PPGI or Galvalume coating.

6. Weather Resistance: With proper sealing and overlap, it performs well in heavy rain and wind conditions.

----------------------------------------------------------------------------------------------------------------------------------

Applications:

* Residential roofing

* Industrial sheds and warehouses

* Commercial buildings

* Agricultural storage sheds

* Temporary shelters and site offices

----------------------------------------------------------------------------------------------------------------------------------

Installation Notes:

* Side-lap: Typically one rib side-lap for water tightness.

* Fasteners: Self-drilling screws with washers at crest of rib for roofing or valley fixing for walling.

* Underlayment: Can be installed with insulation or waterproof membranes underneath.

----------------------------------------------------------------------------------------------------------------------------------

Optional Enhancements:

* Color Coating: Variety of colors to suit architectural preferences.

* Anti-condensation backing: For applications in humid areas.

* Embossed finish: For better grip and appearance.

----------------------------------------------------------------------------------------------------------------------------------

The R101 roof sheet is a type of metal roofing profile commonly used in residential, commercial, and industrial roofing and wall cladding applications. The “R” in R101 often denotes "Ribbed", and 101 usually refers to the effective coverage width of the sheet, typically 1010mm (or 1.01 meters).

This profile features trapezoidal ribs with alternating flat pans and raised sections, providing structural strength, weather

resistance, and an aesthetically pleasing appearance.

----------------------------------------------------------------------------------------------------------------------------------

Key Features of R101 Roof Sheet:

* Effective Width: 1010mm (commonly)

* Rib Height: Generally around 28mm to 32mm

* Pitch (rib spacing): Approx. 203mm between ribs

* Thickness: Usually available in 0.3mm to 0.7mm, depending on application

* Material Options: * Galvanized steel (GI)

* Galvalume (GL)

* Pre-painted galvanized steel (PPGI)

* Aluminum

----------------------------------------------------------------------------------------------------------------------------------

Advantages of R101 Roofing Sheet:

1. High Strength-to-Weight Ratio: Provides excellent structural strength while being lightweight.

2. Easy Installation: Long spans and wide coverage reduce overlaps and installation time.

3. Cost-Effective: Low maintenance, durable, and long-lasting.

4. Versatility: Suitable for roofing, wall cladding, fencing, and even ceiling applications.

5. Corrosion Resistance: Especially when made with PPGI or Galvalume coating.

6. Weather Resistance: With proper sealing and overlap, it performs well in heavy rain and wind conditions.

----------------------------------------------------------------------------------------------------------------------------------

Applications:

* Residential roofing

* Industrial sheds and warehouses

* Commercial buildings

* Agricultural storage sheds

* Temporary shelters and site offices

----------------------------------------------------------------------------------------------------------------------------------

Installation Notes:

* Side-lap: Typically one rib side-lap for water tightness.

* Fasteners: Self-drilling screws with washers at crest of rib for roofing or valley fixing for walling.

* Underlayment: Can be installed with insulation or waterproof membranes underneath.

----------------------------------------------------------------------------------------------------------------------------------

Optional Enhancements:

* Color Coating: Variety of colors to suit architectural preferences.

* Anti-condensation backing: For applications in humid areas.

* Embossed finish: For better grip and appearance.

----------------------------------------------------------------------------------------------------------------------------------

Comparison with Other Profiles:

|

Profile

|

Effective Width

|

Common Use

|

Rib Height

|

Remarks

|

|

R101

|

1010mm

|

Roof/Wall

|

~30mm

|

Widely used, balanced design

|

|

R panel

|

950mm-1000mm

|

Roof/Wall

|

~38mm

|

Taller ribs, heavier load capacity

|

|

Corrugated

|

840mm-1000mm

|

Roof/Wall

|

~17-25mm

|

More traditional look

|

.png?x-oss-process=image/resize,w_100/quality,q_100)

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product Specification

|

Item NO

|

Description |

Offered specification |

|

1.0

|

Roll forming machine

|

|

|

1.1

|

Rolling speed

|

0-12m/min

|

|

1.2

|

Rolling thickness

|

0.3mm-0.8mm

|

|

1.3

|

Raw material

|

Color painted coils, Aluminium, Zinc, Galvanized

|

|

1.4

|

Main Motor

|

7.5KW

|

|

1.6

|

Dimension

|

About 8000×1600×1200(mm)

|

|

1.7

|

Effective width

|

1010mm

|

|

1.8

|

Feeding Coil width

|

1200mm

|

|

1.9

|

Roller stations

|

About 20 stations

|

|

1.10

|

Roller material

|

45#forge steel, coated with chrome

|

|

1.11

|

Shaft diameter

|

Φ75mm

|

|

1.12

|

Transmission

|

By chain 1.2 inch

|

|

1.13

|

Material of chain

|

45# forged steel with frequency quenching, 12A

|

|

1.14

|

Material of cutting

|

Cr12Mov with quench HRC58-62°

|

|

1.15

|

Tolerance

|

10m+-1.5mm

|

|

1.16

|

Hydraulic station

|

4kw

|

Machine List:

|

No.

|

Name

|

Quantity

|

|

1

|

5 ton passive decoiler

|

1 set

|

|

2

|

Main roll forming machine

|

1 set

|

|

3

|

Hydrulic station

|

1 set

|

|

4

|

Servo following cutting

|

1 set

|

|

5

|

Control box

|

1 set

|

|

6

|

Out table

|

2 sets

|

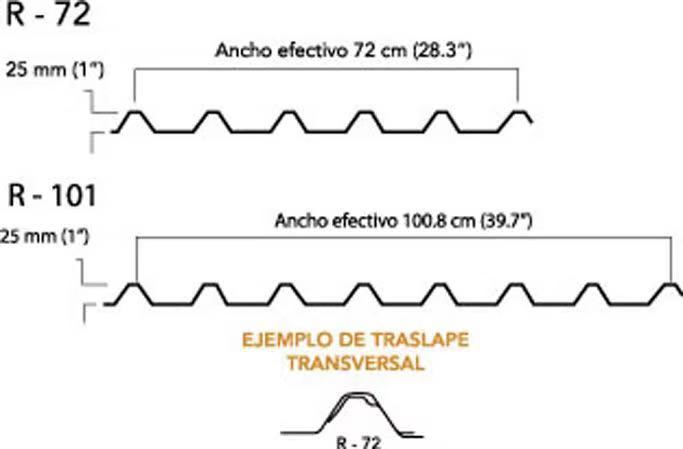

Profile Drawing

Detailed images

5 ton passive decoiler

Main roll forming machine

4 meters passive output table

Hydraulic station

Cantilever control box

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)