Roof Metal Sheet Selflock 700mm Boltless Roll Forming Machine

1.Passive uncoiler 5 ton

2.Main motor power:7.5KW

3.Motor power of hydraulic station:4KW

4.Forming station: about 18 stands

5.Main machine size:8.5 m×1.2m×1.25m

6.Forming speed: 10m/min

7.Diameter of roller shaft:¢76mm

8.Raw material width: as profile

9.Roller surface coating with chrome:single face≥0.05mm

10.Forming thickness:0.3-0.8mm

11.profile according to GB/T12755-91 standards

12.material of cutting blade: Cr12

13.frequency: Delta

14. Computer (PLC)

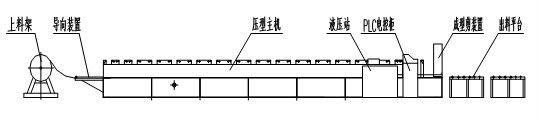

Working Flow:

uncoiling→guide feeding→roll forming→cutting after set length→output

Profile drawing

Application

Boltless System LOCK700-40

Have a high curl and a wide belly thus increasing the batting distance more. Makes the structure economical - Fixing the sheet with the innovation of locking pin 3 in 1 "Superlock 40", which makes it easy to install, locks tightly, closely and is strong

Variety of profiles which suitable for roofing, walling and ceiling application. Due to strength, profile ability for long support spacing

Flexible to curve Lightweight, easy to install, and time saving

Boltless system (Concealed-fixing method) is suitable for applications

Available for straight sheet, curved or convex-concave curve

Rolled-form from High-tensile steel, min: yield strengths are G550 (550MPa) or G300 (300MPa), aluminum/zinc alloy-coated steel and clean colorbond prepainted steel

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

Our display screen is touch screen, not text touch screen.

Sussman roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)