Portable Standing Seam Roll Forming Machine in Truck

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

1.Passive uncoiler: 3 tons for optional

2.Main motor power:2.2KW

3.Forming station: about 6 stands

4.Main machine size:2.5 m×0.9m×1.0m

5.Forming speed: 10m/min

6.Diameter of roller shaft:¢76mm

7.Raw material width: as profile

8.Roller surface coating with chrome:single face≥0.05mm

9.Forming thickness:0.3-0.8mm

10.Frequency: Delta

.jpg)

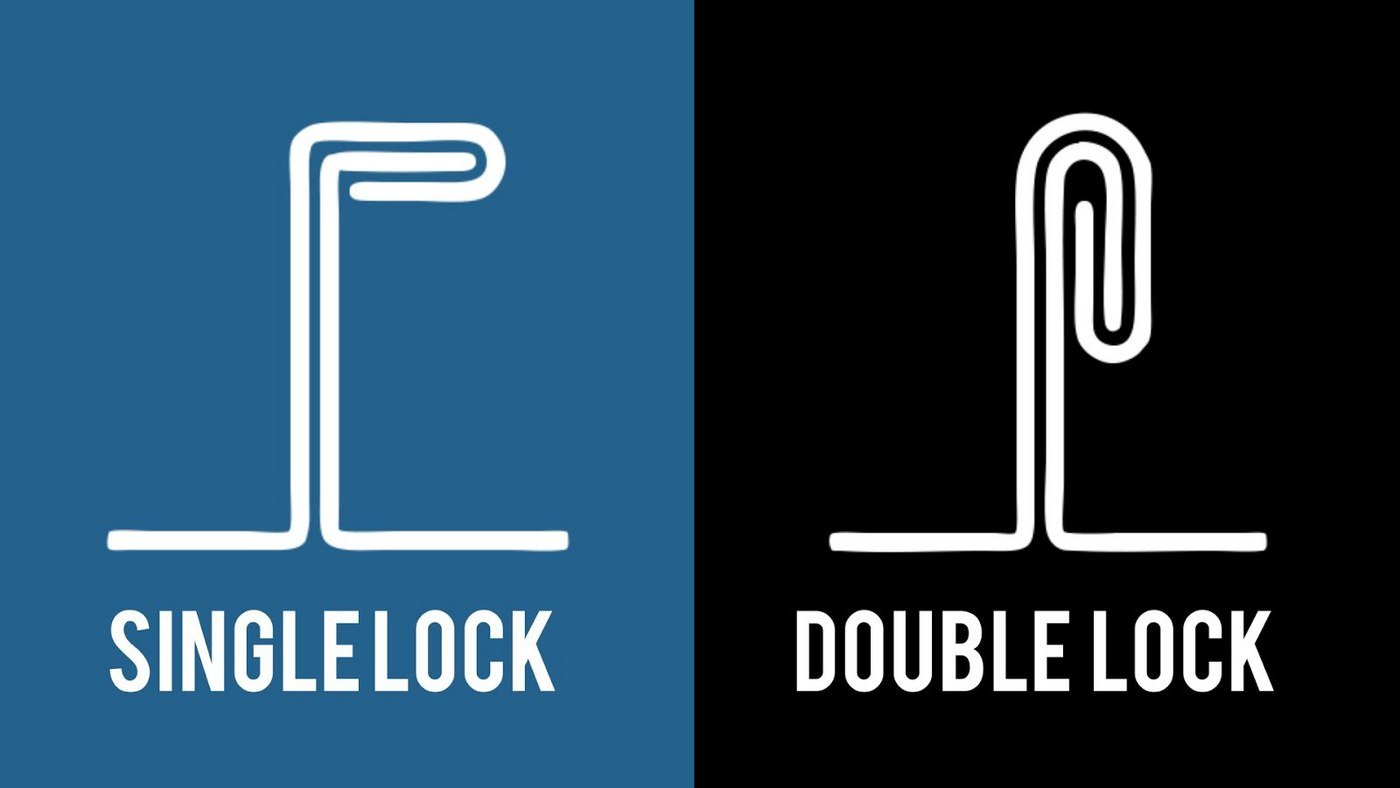

Mechanically Seamed Metal Roof Standing seam drawing

What Is A Mechanically Seamed Metal Roof?

Mechanically seamed metal roofs consist of roof panels with a concealed fastener standing seam system. They are designed with clips that line up with one another so they can be locked together by a mechanical or hand seamer. The way the panels are fastened together makes the roofing more weather resistant and less likely to have any leaking issues.

Faster And More Affordable Installation

The biggest advantage of a single lock system is that less labor is required so your installation goes faster. You’ll find the installation costs to be less for a single lock system as less work is required.

Easier Repairs

A less time-consuming installation is also beneficial if there are problems with your roof in the future. A single lock system makes it easier to replace a damaged panel.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)