High Speed 30m/min Metal Deck Floor Roll Forming Machine

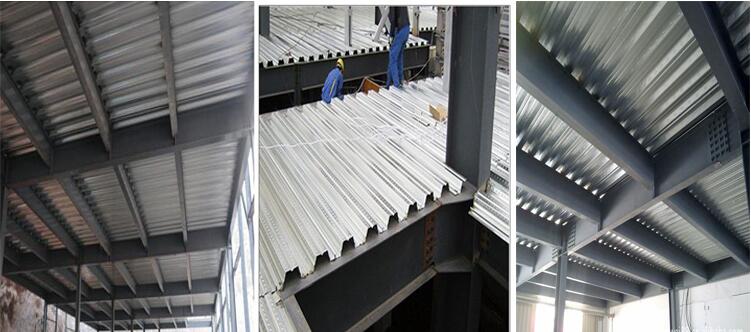

The pressed steel plate supporting the floor concrete is called profiled steel plate, also known as floor deck, steel deck floor.

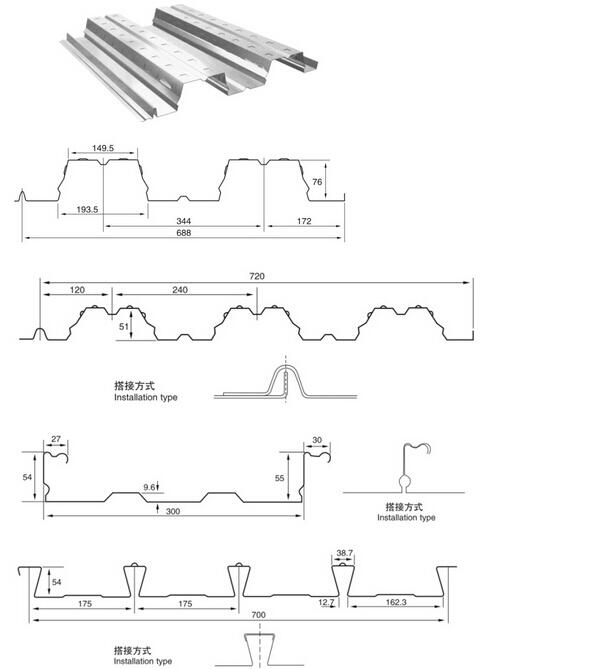

The floor deck is divided into: open floor deck, shrinking deck floor, closed deck floor.

Main feature

1: To meet the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time, and can adopt the flowing water construction of laying profiled steel plates on multiple floors and pouring concrete slabs in layers.

2: In the use stage, the floor deck is used as the tensile reinforcement of the concrete floor, which also improves the stiffness of the floor and saves the amount of steel and concrete.

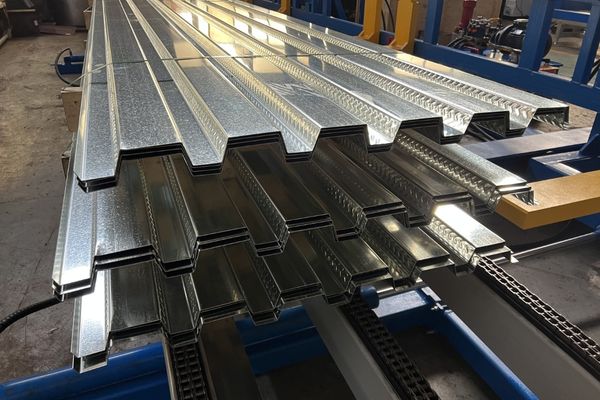

3: Embossing on the surface of the profiled slab maximizes the bonding force between the floor slab and the concrete, making the two form a whole, with stiffening ribs, so that the floor slab system has a high-strength bearing capacity

|

Item NO |

Description |

Unit\Type |

RF-DF |

|

1 |

Steel Thickness |

mm |

0.75-1.5mm |

|

2 |

Forming Speed |

m/min |

0-30m/min |

|

3 |

Roller stands |

stand |

28-30 |

|

4 |

Roller Material |

|

Gcr15 chromed HRC55-60 |

|

5 |

Shaft diameter |

|

Ф90 |

|

6 |

Main Motor Power |

kw |

15*2kw Siemens motor |

|

7 |

Hydraulic cutting Power |

kw |

7.5 |

|

8 |

Hydraulic pressure |

Mpa |

12 |

|

9 |

Power Supply |

|

220V, 60HZ,3 phase |

|

10 |

Tolerance |

mm |

1.5 |

|

11 |

Material of cutting |

|

Cr12mov |

|

12 |

Control system |

|

PLC with touch screen Siemens, and the transducer is Yaskawa |

|

13 |

DRIVE system |

Chain |

1.6 inches |

Deck floor profiles we can make

Details of each composition

Steel deck roll forming machine consists of hydraulic decoiler (uncoiler), front pre-cutting device, guiding device, roll forming, servo following cutting, conveyor tables, products packaging machine and Siemens electrical control box system. With full and special experience, we can customize steel deck roll forming machines according to customers’ profile drawings and specifications.

1. 25 Tons hydraulic decoiler to hold raw material

2. Pre-cutting

3. Embossing rollers

4. Main roll forming machine

5. Servo following cutting

6. 12meters Auto stacker

7. Products packaging

The products are widely used in power plants, electric equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminal buildings, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, and Olympic venues. Stadiums and other steel structures.

.bmp?x-oss-process=image/resize,w_100/quality,q_100)