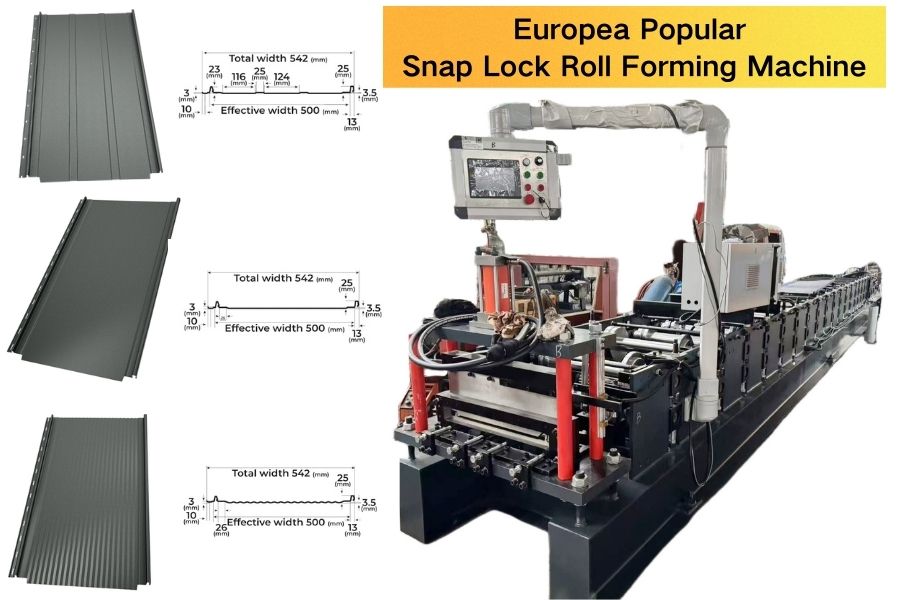

Europea Popular 500mm Width Coverage Snap Lock Roll Forming Machine

Folded sheet metal roof panels with joint clicking are a modern solution in the production of roofing and a quick and easy alternative to traditional roofs “with rebate”. This type of metal roofing can be chosen to cover rustic houses or ordinary roofed houses, requiring renovation, but also for new and modern buildings.

Retro Panel covering flexibility allows to cover large slope buildings, ensures coverage of atypical buildings such as heritage buildings, keeping the architectural line of the building.

Technical Data:

Rolling Speed : 0-8m/min(cutting time is not include)

Steel sheet Thickness: 0.3-0.7mm color painted sheets

Coil width as profile

Control System: PLC Siemens

Roller Stations: about 16 stations

Roller Material : 45# forge steel, coated with chrome

Shaft Material and DIA:¢70mm,material is 45# forge steel, Chrome with quenching

Main Motor Power: 4kw

Hydraulic Pressure: 12Mpa

Material Of The Stations: Wall plate thickness 16mm

Tolerance: +1.5mm

Power supplier: 380V, 50HZ,3 phases

Way Of Drive:1 inch single chain

Color Of The Machine :customer’s need)

The size of the forming machine:7500*800*1000mm

Machine weight: about 3.5 tons

Machine List:

|

5 ton passive decoiler |

1 set |

|

Hydraulic notch device |

1 set |

|

Main roll forming machine with roller punching |

1 set |

|

PLC Control box |

1 unit |

|

Hydraulic station |

1 unit |

|

4 meters passive table |

1 unit |

|

Hydraulic cutting device |

1 unit |

Profile Drawings:

Working Flow:

Uncoiling—Feeding with guide—Roll forming—hydraulic cutting—Products collecting

Application:

Advantages:

- quick and easy installation

- undeniable aesthetic of the steep slope roof

- panels without visible fasteners (screws)

- longitudinal pre-profiling to increase roof stiffness

- possibility to execute the roof with a slope of min. 8⁰

- wide range of colors

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)