Quick Change Automatic C Z Purlin Roll Forming Machine

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

C Z Purlin Roll Forming Machine

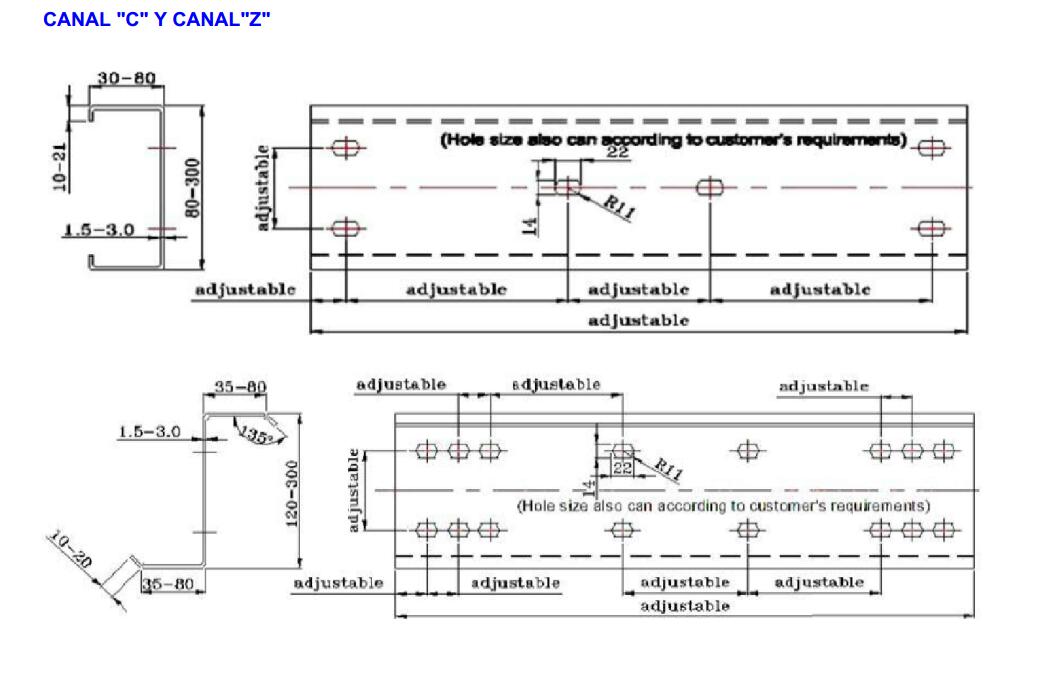

This C/Z Quick Interchangeable Roll Forming Machine, which to make C ( Cee) profile and Z (Zee) profile.

The rollers for C&Z are changed very quickly without dismantle any parts , if you are familar with the machine, it takes about 30 minutes to one hour to change.

One machine can produce the specifications of C/Z purlins with web width 4" to 12", and the width of the purlins can be automatically adjusted by PLC.

If you need more faster, we can handle fully auto change from C to Z purlin adjusting as well.

This machine we adopt Pre-cutting and pre- punching system, only need one cutting to make all sizes, no need to change the cutter balde, which save labor

|

C/Z Quick Interchangeable Machine

|

|||

|

No

|

Item

|

Specification

|

Optional

|

|

1

|

Suitable material

|

Type:Galvanized Coil, PPGI, Carbon steel Coil

|

|

|

Thickness(mm):1.5-3.5mm

|

|||

|

Yield strength: 250 - 550MPa

|

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa

|

|||

|

2

|

Nominal forming speed(m/min)

|

8-15

|

Or according to TEMPyou're requirement

|

Profile drawing can be also customized as client's request

Types of Steel Purlins

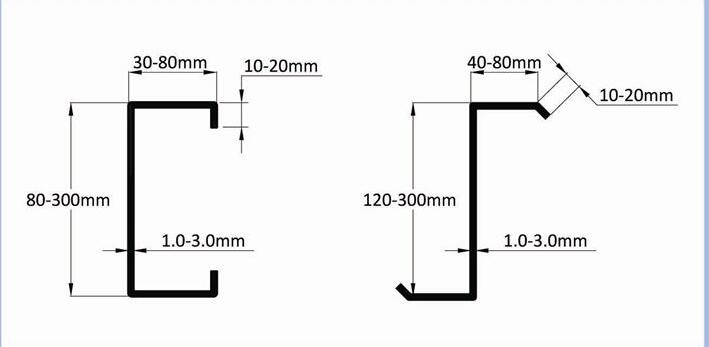

C Purlin

C purlin, like its name, is designed to form a C shape. People also call it Cee section purlin or C section purling. Professionals mainly use C purlins to support floors and walls. Their design makes them ideal for supporting the beams needed for flooring.

Advantages of C Purlins

- It is sturdy

- Guaranteed alignment

- Has the capacity to cover a distance

- Side drilling is not necessary

- It does not need cutting

Z Purlin

Z purlins are z-shaped purlins commonly used at overlaps and joints. They are horizontal beams designed to give form to a building’s shell structure’s wall joists and roof. Z purlins (Zed purlins) act as a sheet aid between the building and roofing sheets to ensure that the sheets are fixed firmly and held in place.

This purlin type is lightweight and highly flexible. These properties make them popular for use in industrial and agricultural buildings. The Z purlin shape aids in overlaying the joints, making them stronger and more durable than C purlins. Their strength makes them perfect for large structures.

Advantages of Z Purlins

- Stronger than C purlins

- Reduces purlins’ height and, therefore, saves materials

- You can overlap them

Spacing for Roof Purlins

It is important to consider the spacing for metal purlins before erecting the system. The rule of thumb is that the heavier and bigger a metal roofing structure is, the greater the space you need to leave between the principal rafters and purlins.

In most structures, the standard spacing is between 12″ and 24.” However, this standard has some exceptions due to the customers’ requirements. Many manufacturers of metal roof purlins and building regulations advise that:

- When supporting secondary framing and steel framing, you shouldn’t space the purlins apart beyond 30 inches. When supporting sheathing, they should be 38 inches apart.

- Engineers and contractors should use excellent judgment when spacing metal roofing purlins during constructions that have a light frame for lengthy spans.

When spacing your purlins, you can consider the following tips:

The center-to-center spacing should not exceed 30 inches if there are over five purlins in a span. You can utilize more purlins in a situation like that.

Design the purlins in pairs in a situation where the roof span is greater than 50 feet, with a higher purlin at the center supporting two lower spans spaced 30 inches away from each other.

Place one end post for each lengthy span. The end post must be at least 200 feet long and have a bearing plate installed to give the purlins support.

Size of Roof Purlins

Manufacturers produce purlins in different sizes, known as gauges. The two types of purlins, C purlins, and Z purlins, are available in three different sizes: 16 gauge, 14 gauge, and 12 gauge. You may have to consult an expert to determine the most suitable size for your building project.

What Purpose Do Purlins Serve In Construction?

Purlins are divided into two types: roof purlins and regular purlins. In the prefabricated steel structures, builders often connect the purlins with round or V-shaped bars to firmly stabilize the purlin system.

For columns of large factories with heights of 9-12m, purlins are supported by V-shaped struts to enhance the bearing capacity of the works. In addition to the role of bearing the roof load and human load, purlins are calculated and designed to bear the hanging load of wind ceilings, duct systems, electricity or decorative furniture.

Purlins are a specialized material used in frameworks and prefabricated houses to structural support and prevent rust and termites.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)