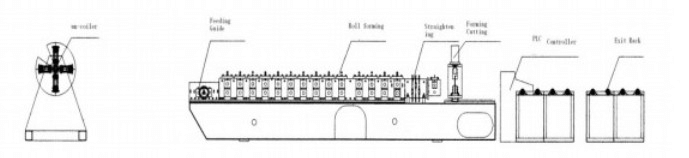

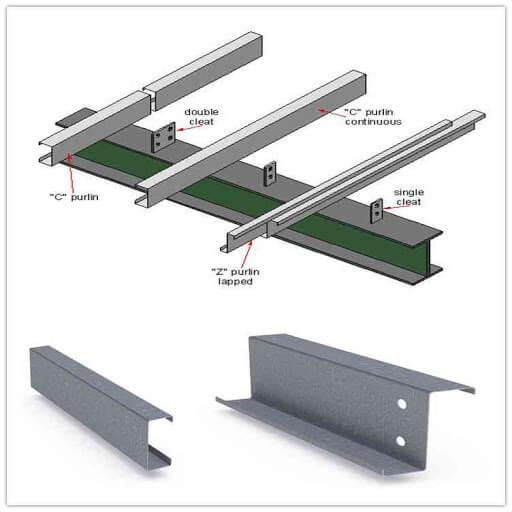

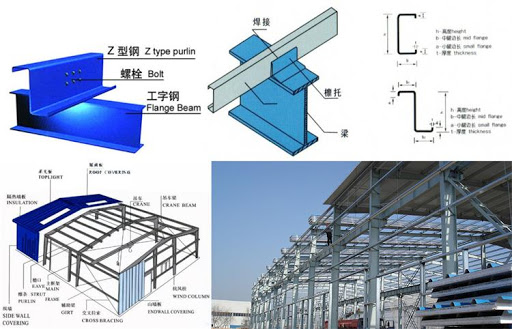

CZ Interchangeable Steel Frame Purlin Roll Forming Machine

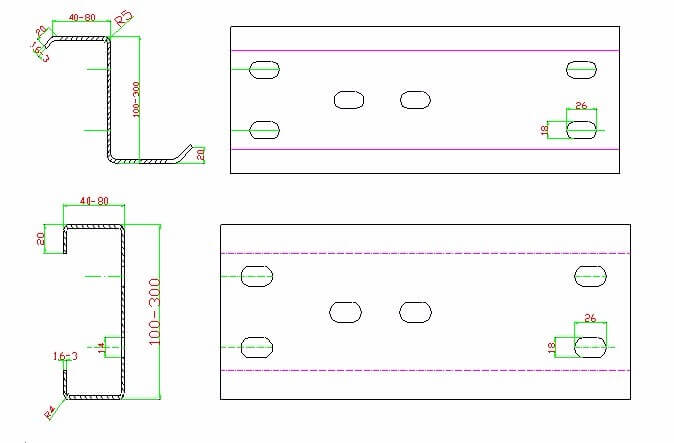

This C/Z Quick Interchangeable Roll Forming Machine adopts a special structure. The rollers for C&Z are changed very quickly without dismantle any parts . One machine can produce all specifications of C/Z/U purlins . Crimples are optional to increase rigidity of purlins. Teh width of the purlins can be automatically adjusted by PLC. If you need more economy dat can be handle wheel adjusting as well. dis machine we adopt Post-cutting and punching system, only need one cutting to make more size, the cutting blades can move up and down, left and right to save time to change blades.

|

C/Z Quick Interchangeable Machine |

|||

|

No |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):1.5-3.0 |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-15 |

Or according to you're requirement |

|

3 |

Forming station |

18 |

|

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Driving system |

Chain drive |

Gearbox drive |

|

6 |

Rollers’ materail |

GCr15 |

Cr12 |

|

7 |

Station structure |

Wall panel station |

Forged Iron station |

|

8 |

Punching system |

Yes |

Hydraulic punching station or Punching press |

|

9 |

Cutting system |

Post-cutting |

Post- universal cutting |

|

10 |

Power supply requirement |

380V 50Hz |

Or according to you're requirement |

|

11 |

Machine color |

Industrial blue |

Or according to you're requirement |

Working Flow:

Uncoiling—feedingwithguide—Punching——Rollforming——Cutting—Products collecting

Please send us your profile drawings.

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

Our display screen is touch screen, not text touch screen.

Sussman roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.