Rubber Belt Production Line For PU Sandwich Panels Making 16mm Thickness

4BVRZT.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Primary Technology Parameters Product Line:

1. PU foam thickness: 16mm, aluminum and galvanized coil thickness 0.27-0.4mm

2. Linear Speed of production:About5-6 meters per minute

3. Maximum Roller Forming speed:6meters per minute

4. Reciprocating times of injection head per minute <60

5. Production type: totally continuous production with PLC controlling

6. Composite structure:position fixed by double rubber tracker

7. Foaming system: totally automatically continuous foaming, quantity of foaming could be stepless adjustable

8. Main Power of production 50KW

10. Electronic controlling system: full-frequency PLC controlling system.

Roll Forming machine

Each Roller forming machine consists of the decoiler, main roller forming machine is equipped outside of the line, which is used to form on the coil of color steel of maximum 500mm in width and 0.27~0.4mm in thickness while exerting certain pressing force.

| NO. |

Composing of product line |

Details |

Amount |

| 1 |

Roll Forming Machine |

For 383mm flat |

1 |

| 2 |

De-coiler |

5 ton hydraulic decoiler |

1 |

| 3 |

Embossing machine |

For embossing patterns | 1 |

| 4 |

Assembling machine |

PU two component Liquid mixing and injecting section for foaming low pressure |

1 |

|

|

Pre-heating machine |

1 | |

|

Laminating device |

1 | ||

|

Panel automatically cutting system |

1 | ||

|

Dust collector |

1 | ||

|

PU assembling conveyor system(rubber belt) |

1 | ||

| 5 | Secondary painting machine |

Secondary painting machine |

1 |

| 6 |

PLC control panel |

Siemens |

1 |

| 7 |

Passive out-table |

6 meters in length |

1 |

4BVRZT.jpg)

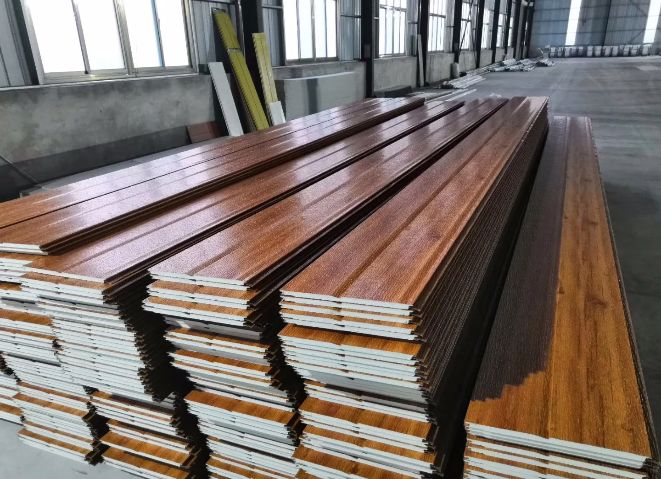

Profile we make