Discontinous PU Sandwich Panel Line

Features of Factory supply discontinuous PU sandwich panel manual press production machine line

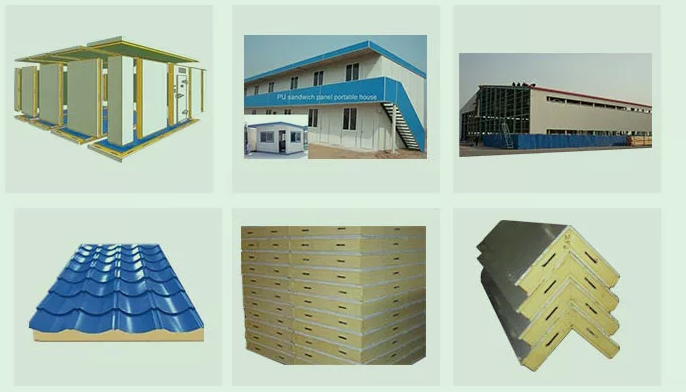

1. Machine is to produce the sandwich panel with the color steel sheet or galvanized sheet (PPGI) on upper and lower sides and the core of polyurethane (PU) or Polyisocyanurate (PIR) insulated material.

The multi-layered laminator is consisted of the press and the rail stands. Two worktables move into the press and the other two stay on rail stands. Initially, put the top and the bottom sheets inside of mould frames and then seal, after that, feed the worktables into the press. When worktables inside the press moves out orderly, the other two feed in at the same time. Upon the finish of feeding, the press will close and slant at a angle, waiting for injecting PU raw materials from the PU mixing head into different panels. Meanwhile materials start foaming and curing. At this time, mould frames on worktables moved out for taking out the finished products, then to be ready for next production cycle.

The main laminator 2+2 produces PU sandwich panel with fixed length such as 6m, 9m, 12m, adjustable width less than 1.2m, different thickness from 50mm to 250mm by the closed molding frame.

a. Uncoiler

Type of uncoiler: manual

Material of coil: color coating coil

Thickness of sheet: 0.3~0.8mm

Width of coil: 1000mm,1200mm

Weight of coil:≤ 5 t

Inside diameter of coil: 480~520mm

Apply guard film

Type of apply guard film:automatic

into shearing

Type of shearing: electrical shearing

Driven power:0.75 kw

Edge forming machine for wall

Design of profile: see drawing attached

Type of forming: one layer forming

Roller diameter: ¢72mm

Material of roller:45 steel heat treatment

Thickness of chromic plating of roller surface:0.05~0.06mm

Speed of forming:0~12m/min synchronies with panel machine

Type of synchronies: electrical synchronies

Driven power:7.5 kw

Installation instruction: two parts

Size of forming machine:8000×2200×2200mm

Weight of forming machine:~6 t

Include various groups’ pipes and hydraulic pipes, to transport the A/B groups’ materials and the hydraulic oil.

b) Electric power source and the equipment weight and occupational area

Electric power source: 380V/50HZ

Control voltage: AC 220V

Input Power: 60KW

Weight: 200KG

Occupational area: 1500mm*3300mm* 2799mm