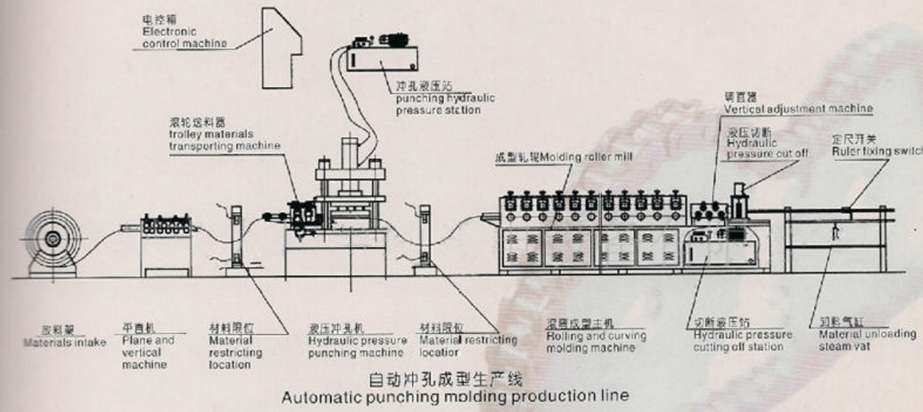

Racking Shelf panel machine

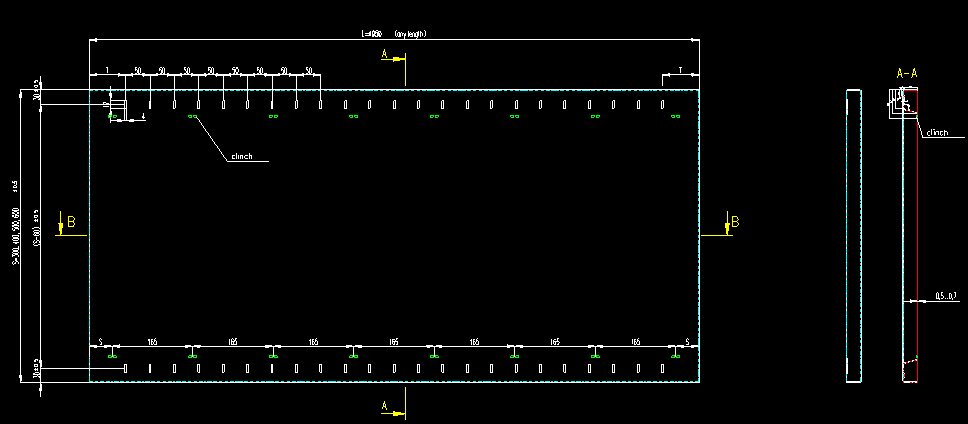

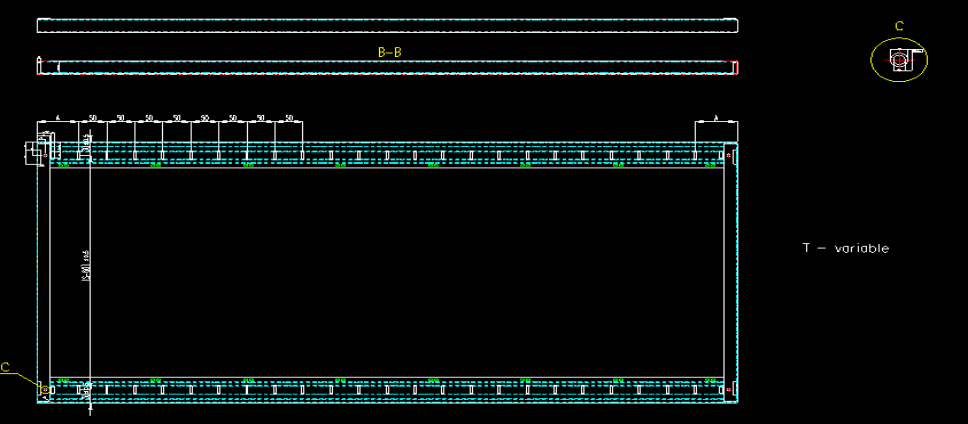

Profile of the product (Basis on customer’s requirement to design)

Size 300mm, 400mm, 500mm and 600mm make in one machine, change the size automatically

|

Machine List

|

Name |

Quantity (set) |

|

5 Tons electric De-coiler |

1 set |

|

|

Servo feeding |

1 set |

|

|

Hydraulic punching device |

1 set |

|

|

Punching dies |

2 sets |

|

|

Bending moulds |

2 sets |

|

|

Hydraulic cutting and bending machine |

1 set |

|

|

Main roll forming machine |

1 set |

|

|

Conveyor belt |

1 set |

|

|

Run out table |

2 sets |

|

|

Control panel |

1 set |

|

|

Safety Cover |

1 set |

|

|

Spare parts |

1 package |

The technique data

- 1. Materials to form: According to the customers’ requirement Used for 300mm,400mm,500mm600mm width,material thickness 0.5-0.7mm galvanized steel,length is variable from 0-10000mm

- 2. Forming steps: About 26steps

3.Material of rollers:GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers: >¢150

- 4. Material of main shaft : 45# high quality steel (diameter>¢50), driven by chain

- 5. Chains’ material: 45# steel, high frequency quenching, circular pitch:1; number of teeth: 1

- 6. Cutting: Hydraulic cutting; quenching HRC58-62

- 7. Electronic control: PLCcontrol

- 8. Dimension of machine: About 12000mmX2000mmX1200mm

- Weight: About 10Tons

- 10. Drive system: Chain drive, 11KW main motor power+2.9KW servo motor, working speed:about 2-3m/min;

- 11. Welding structure: material of fixed beam and walking beam: hot-rolled steel, the base and rack are be gantry planer processing after welded, work platform is not allowed stress deformation; main machine table-board’s plainness <2mm/1000mm

- 12. Punching: Punching the holes at the press machine before forming the shapes

- 13. Bending: Bending after the hydraulic cutting

- 14.Encoder:Omron brand

- 15.Electric parts: Schneider brand

Working flow

5 tons Electrical De-coiler——→ Servo feeding—→ Hydraulic punching—→Main roll forming machine—→Hydraulic cutting-- Conveyor belt---Bending one side--Bending two sides—→ Run out tables