High Speed CNC Control Metal Sheet Folding and Slitting Machine

1.Technical parameter

1) Type: WHZW6000

2) Working length: 6200mm

3) Press head: 7

4) Weight: 5400kg

5) Pressing power: 130kn

6) Bending range: 0-1250

7) Depth of throat:: 800mm(Max. working width of material in clamp)

8) Folder low worktable: back and forth 27mm, with quad of 12.7mm can be knock down

9) Width of up and low worktable:28mm

10) Hinge: parallel four connected pole

11) Act component of worktable: hydraulic double oil cylinder

12) Circle time: Max. bending limit take about 12 seconds

13) Motor power of hydraulic station:11kw

14) Total power: 11.5kw 15) Outline dimension length×width×height:9395×1842×1375mm

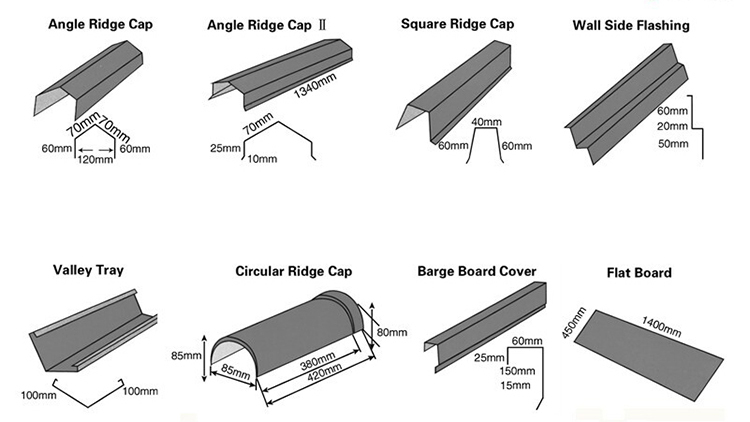

This metal sheet fold machine is used for the ridge cap, roof flashing, end cover, gutter, trim, cornice, door opening, window and so on, it also can used for processing metal plate of other industry.