Metal Roller Shutter Door Bottom Roll Forming Machine

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

|

Items |

Specifications |

|

|

Material of coil |

Material Thickness |

0.5-1.0mm galvanized steel |

|

De-coiler |

Weight |

3 tons manual |

|

Forming system |

Rolling Speed |

About 8-12 m/min |

|

|

Roller Stations |

About 23 stations forming |

|

|

Roller Material |

Cr40 Steel with quenching |

|

|

Shaft Material |

45# Steel Diameter 60mm shaft

|

|

|

Maim Motor Power |

5.5 kw |

|

|

Hydraulic cutting Power |

4 kw |

|

Cutting system |

Material Of Cutting |

CR12Mov with quench treatment |

|

|

Hardness |

HRC58-62 |

|

|

Tolerance |

+-1.5mm |

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase

|

|

|

Control System |

PLC Delta |

|

|

Weight |

About 6 tons |

|

|

Way Of Drive |

1 inch single chain |

|

|

Size of machine |

Length 8000mm* Width 800mm* Height 1200m |

|

|

Operation worker |

2 workers |

1.This machine is made up of roll forming machine,manual decoiler,cutting machine,PLC computer control and out put table.

2.The machine is stable,no noise,no shake.

3.It drives by chain, 23 rollers number to make best products.

4.The touch screen is hang over, it is not under the floor.

5.When you get the machine,it is no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working.

And the profile is as follows, also we can customized as your requirements

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

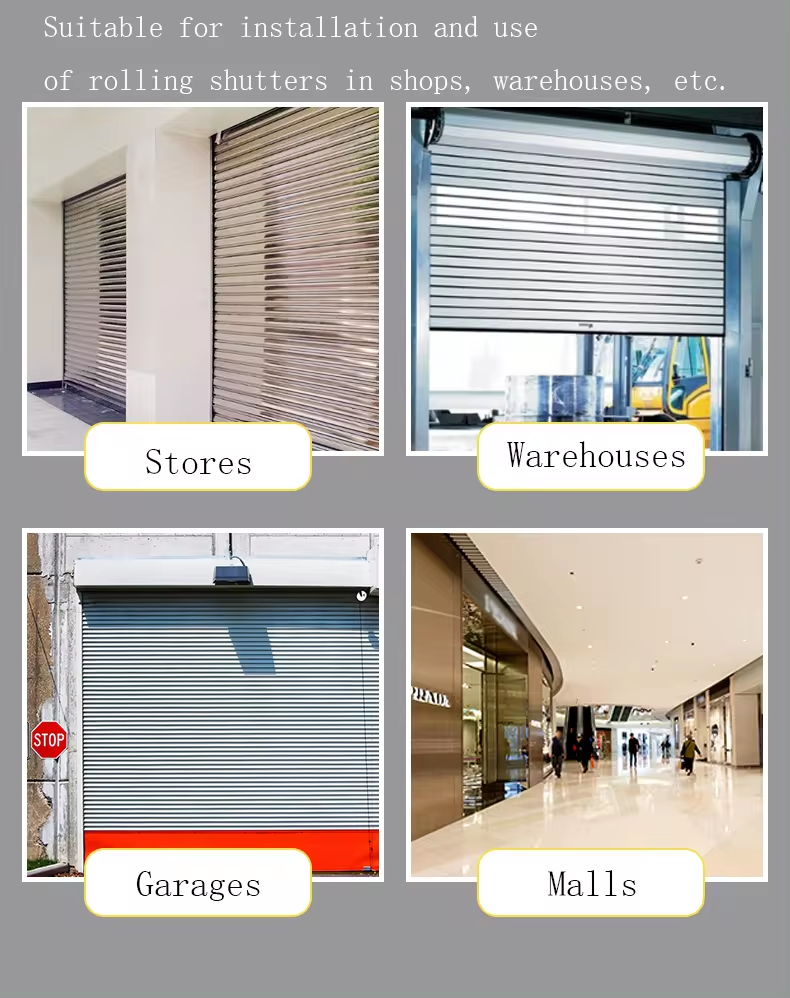

‘L’ section bottom rail used on standard roller shutter doors, the Bottom roller shutter door seal can also act as a deterrent against pests. And helps with any unwanted leaves and dust.