High Speed 50-120m/min C Stud U Truck Drywall Roll Forming Machine with Servo Following Cutting

.jpg)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

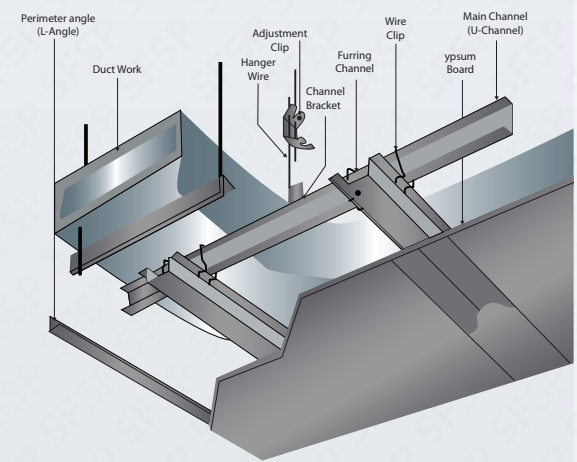

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes steel, also we can customize the size as your requirement.

Thickness is normally 0.4mm to 1.2mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensil steel.

If you need to more efficiency then we recommend you Flying shear cutting with No-stop system, the machine speed can reach about 50-120M/min.

Also you can choose automatic stacker, or without it, but with it you can save labor cost, for the stacker, we have simple or automatic for your optional.

Machine list

|

Machine list |

3 ton passive de-coiler |

1 set |

|

Main roll forming machine |

1 set |

|

|

Punching device |

1 set |

|

|

Non stop cutting device |

1 set |

|

|

PLC Control box |

1 unit |

|

|

Hydraulic station |

1 unit |

|

|

Out table |

2 units |

|

|

Safety cover |

1 unit |

Parameter

|

|

Items |

Specifications |

Remarks |

|

Material of coil |

Thickness |

0.4-1.2mm galvanized steel |

|

|

De-coiler |

Weight |

3 ton manual |

|

|

Forming system |

Rolling Speed |

50-120m/min |

|

|

Embossing |

At sides or without |

|

|

|

Roller Stations |

About 13 stations forming |

|

|

|

Roller Material |

Cr40 Steel with quenching |

|

|

|

Shaft Material |

45# Steel Diameter 60mm shaft

|

|

|

|

Motor Power |

30 kw |

|

|

|

Hydraulic cutting Power |

7.5 kw |

|

|

|

Cutting system |

Material of cutting |

CR12 with quench treatment |

|

|

Hardness |

HRC58-62 |

|

|

|

Tolerance |

+-1.5mm |

|

|

|

Cutting blade |

1 set of cutting blade |

|

|

|

Electrical control system |

Electric Source |

380V, 60HZ,3 phase

|

|

|

Control System |

PLC |

|

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)