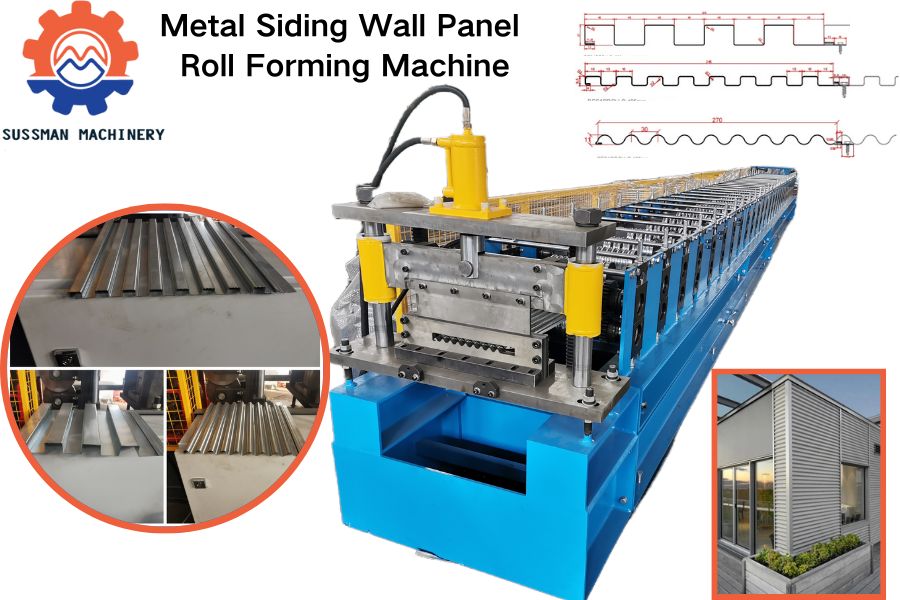

Chile Popular Facade Wall Siding Panel Roll Forming Machine

This machine is for an Chilean customer, one machine to make 3 different type of wall siding panel. The shapes are changeable by cassette.

Technical data:

|

Item NO |

Description |

Offered specification |

|

1.1 |

Rolling speed |

10-12 meters/minute |

|

1.2 |

Rolling thickness |

0.3mm-0.8mm |

|

1.3 |

Raw material |

Aluminum,Galvanized steel coils or PPGI |

|

1.4 |

Main motor |

5.5kw*2 |

|

1.5 |

Hydraulic motor |

5.5kw |

|

1.6 |

dimension |

8000×700×1000(mm) |

|

1.7 |

Roller stations |

About 22-24 stations |

|

1.8 |

Roller material |

45#forge steel, coated with chrome |

|

1.9 |

Shaft diameter |

Φ70mm,material is 45# forge steel |

|

1.10 |

Transmission |

By chain 1 inch |

|

1.11 |

Material of chain |

45# forged steel with frequency quenching, 12A |

|

1.12 |

Material of cutting |

Cr12Mov with quench HRC58-62° |

|

1.13 |

Tolerance |

6m+-0.5mm |

|

1.14 |

Frame |

H type steel |

|

1.15 |

Voltage |

220V, 60hz, 3phases |

Machine List:

|

No |

Name |

Quantity |

|

1 |

5 Ton Passive De-coiler |

1 set |

|

2 |

Front Manual Cutting |

1 set |

|

3 |

Lamination Device |

1 set |

|

4 |

Main Roll Forming Machine |

1 set |

|

5 |

Hydraulic Cutting |

1 set |

|

6 |

Control Box |

1 unit |

|

7 |

Hydraulic Station |

1 unit |

|

8 |

Output tables |

2 units |

|

9 |

Safety Cover |

1 unit |

|

10 |

Spare Part |

1 Package |

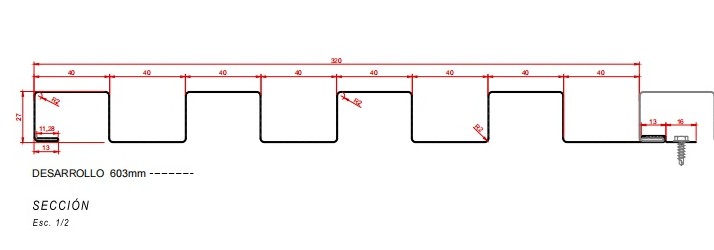

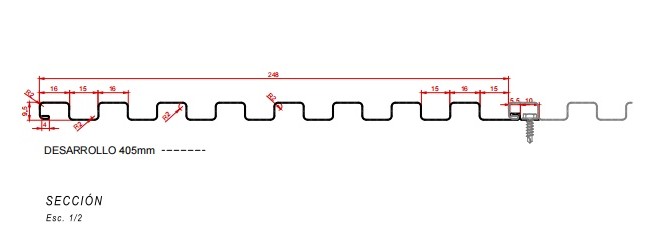

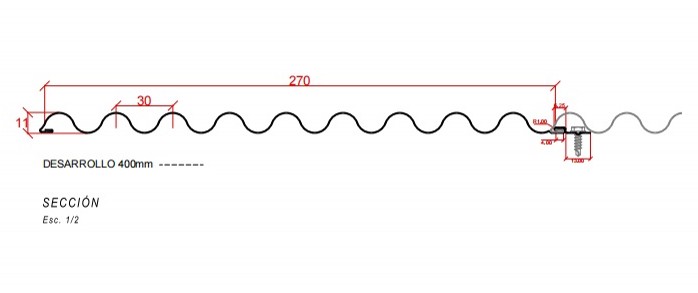

Profile Drawing:

One machine with 3 cassette

Application:

.jpg)

.jpg)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)