3" 4" Round Downspout Tube Roll Forming Machine

.jpg)

Down Pipe forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, continuous rolling and cold-forming, automatically cut to the size and specification which is required, and output the finished panels. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

Technical Data:

- Machine specification: Material: can be steel, colored steel or aluminum,

Material thickness: 0.3-0.6mm, yield strength 250 Mpa to 550 Mpa, coil width is according to the final profile, length is up to 12 meters

- Forming speed: 0-5meters/minute

- Forming roller: about 20stations

- Main motor power: 7.5KW

- Hydraulic station power:5.5KW

- Roller material: 45# forged steel, surface coated with chrome

- Main shaft material: 45# steel

- Main axis dia.: ¢68mm

- Hydraulic cutting pressure: 10-12Mpa

- Cutting method: hydraulic powered, cutting after roll forming.

- Cutting blade material: Cr12Mov quenching treatment

- Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

- Drive method: Chain drive, made in China

- Electric parts: Schneider brand

- Touch screen: Delta

- PLC: Delta

- Encoder: Omron

- Transducer:Yaskawa

Machine List:

|

Serial No. |

Commodity & Description |

Quantity |

|

1 |

3T manual uncoiler |

1 set |

|

2 |

Feeding with guide |

1 set |

|

3 |

Main roll forming machine |

1 set |

|

4 |

Straighten device |

1 set |

|

5 |

Hydraulic cutting equipment |

1 set |

|

6 |

Output table |

1 set |

|

7 |

Main drive |

1 set |

|

8 |

Hydraulic system |

1 set |

|

9 |

Controlling system (including cabinet) |

1 set |

|

10 |

Downpipe elbow bending machine &Seaming machine |

1 set |

|

11 |

Safety cover |

1 set |

|

12 |

Spare parts |

1 package |

Working Flow:

Uncoiling – Infeed Guiding– Roll forming – Straighten – Hydraulic cutting – Run-out table-elbow-seaming

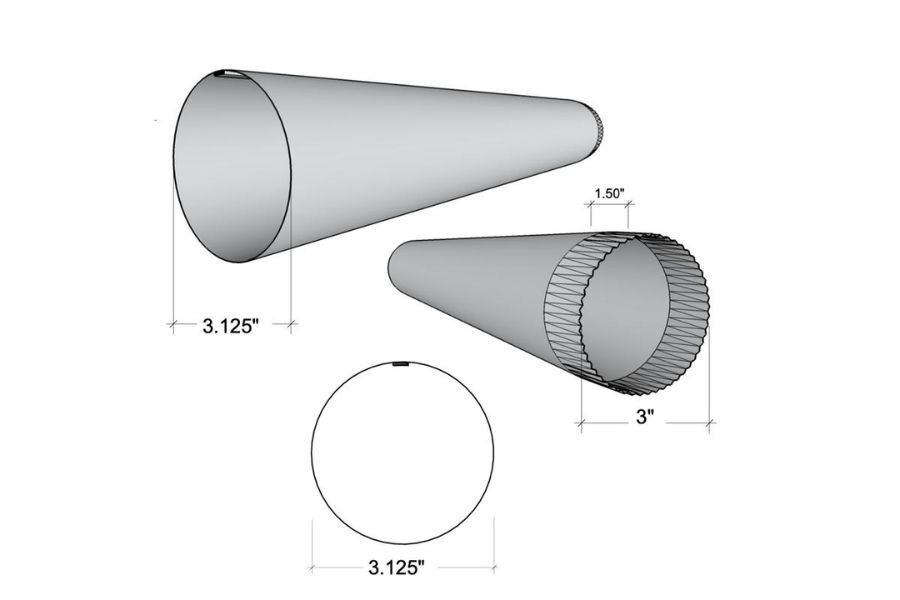

Profile Drawing:

Application:

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)