The profile:The thickness of sheet: 1.5-6mm

|

FOB Shanghai Port |

10 ton hydraulic Un-coiler with coil car |

1 set |

|

|

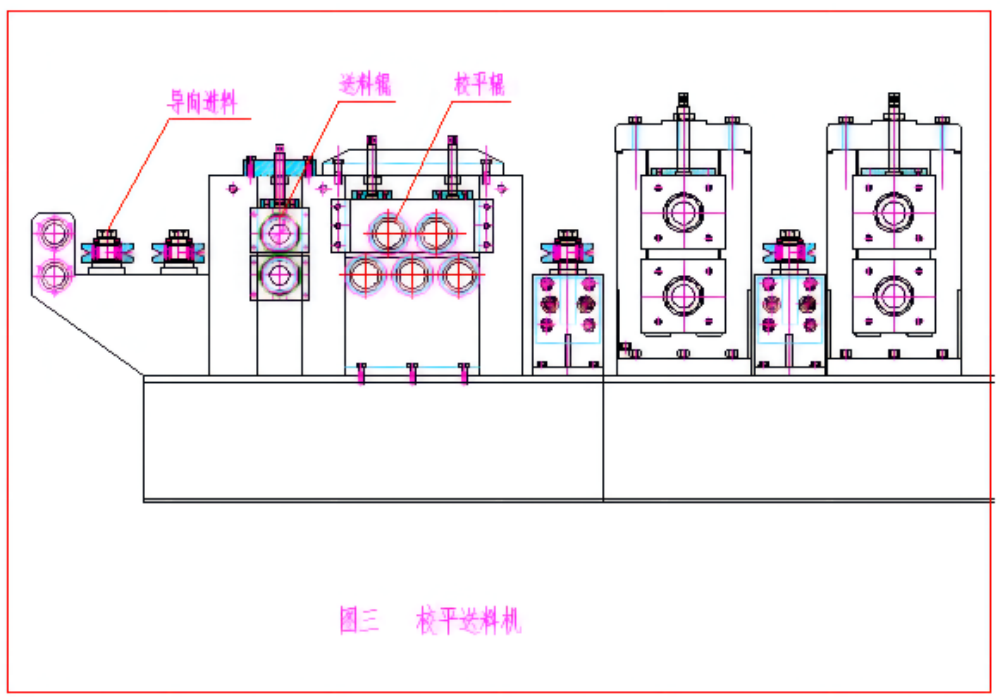

Feeding and leveling device |

1 set |

|

|

Hydraulic punching device |

2 sets |

|

|

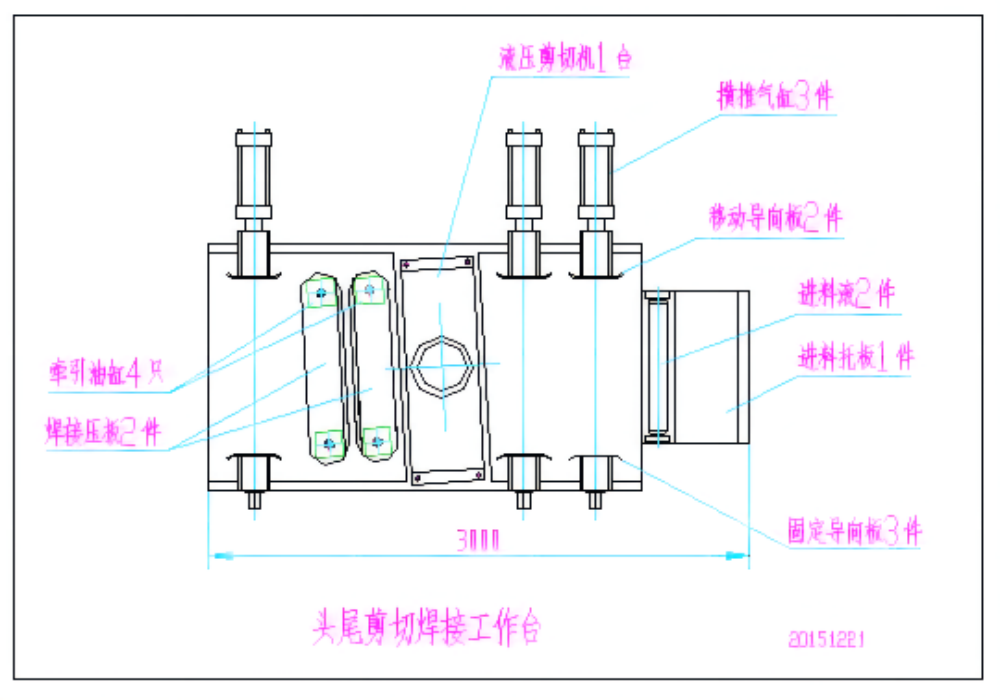

Cutting and Weld device |

1 set |

|

|

Main roll forming machine |

1 set |

|

|

Hydraulic press machine 600 tons |

1 set |

|

|

Punching moulds for press machine |

1 set |

|

|

Servo following Cutting |

1 set |

|

|

Control box |

1 unit |

|

|

Hydraulic system |

1 unit |

|

|

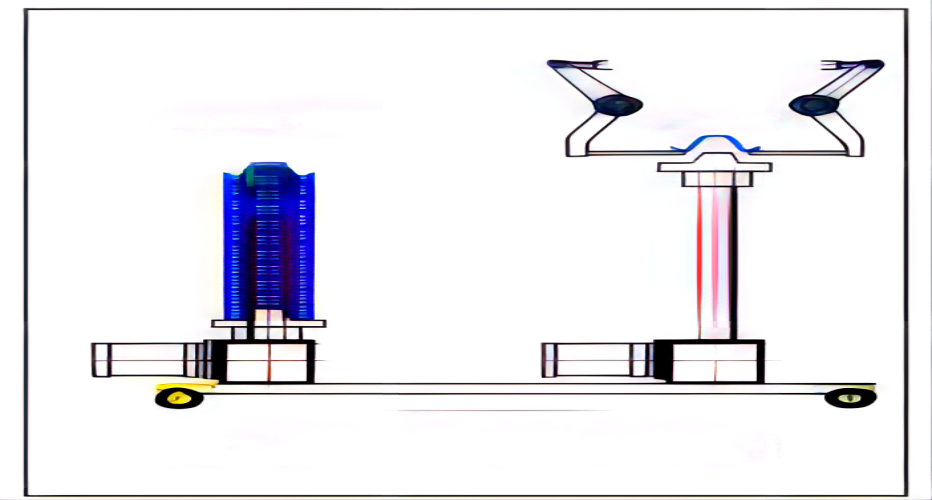

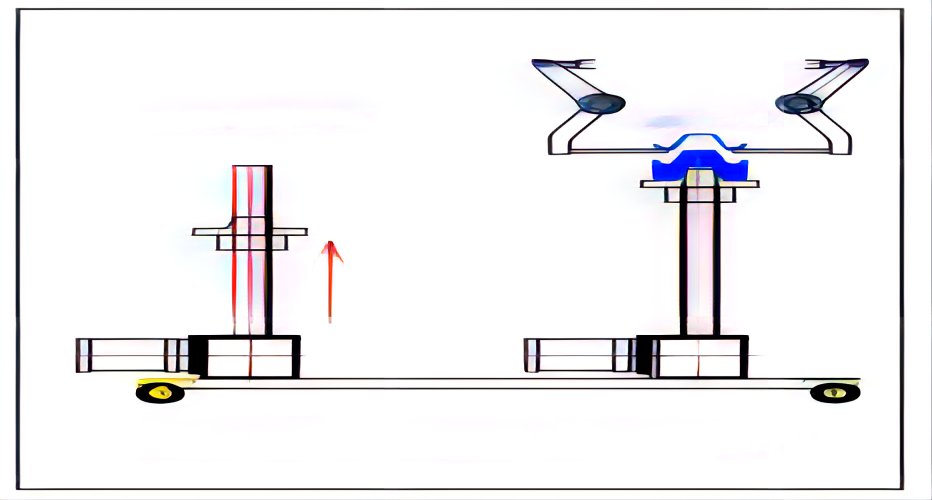

6 meters auto stacker |

1 unit |

|

|

Subtotal FOB Shanghai |

|

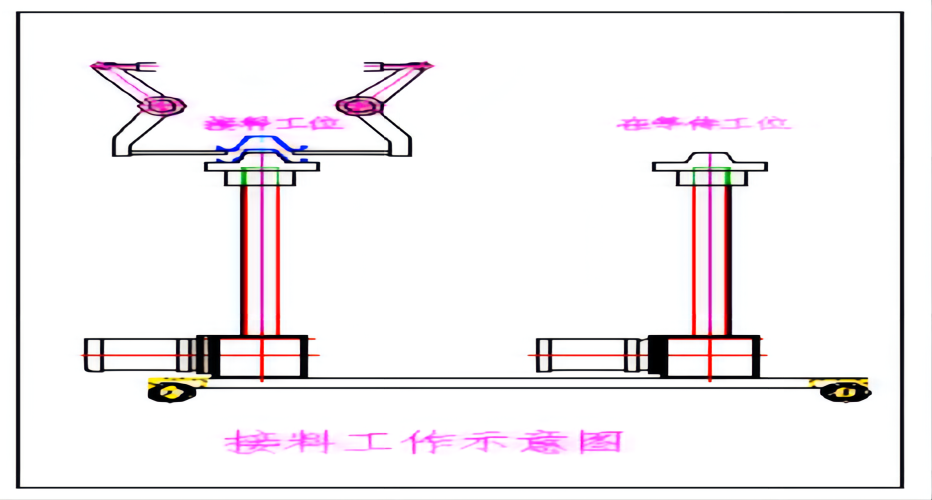

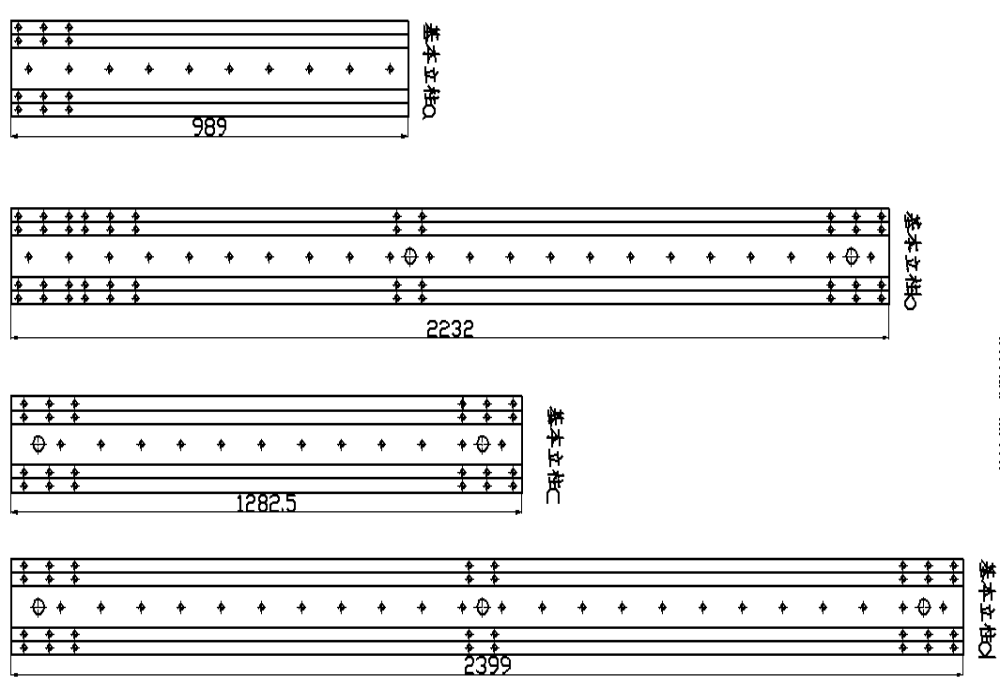

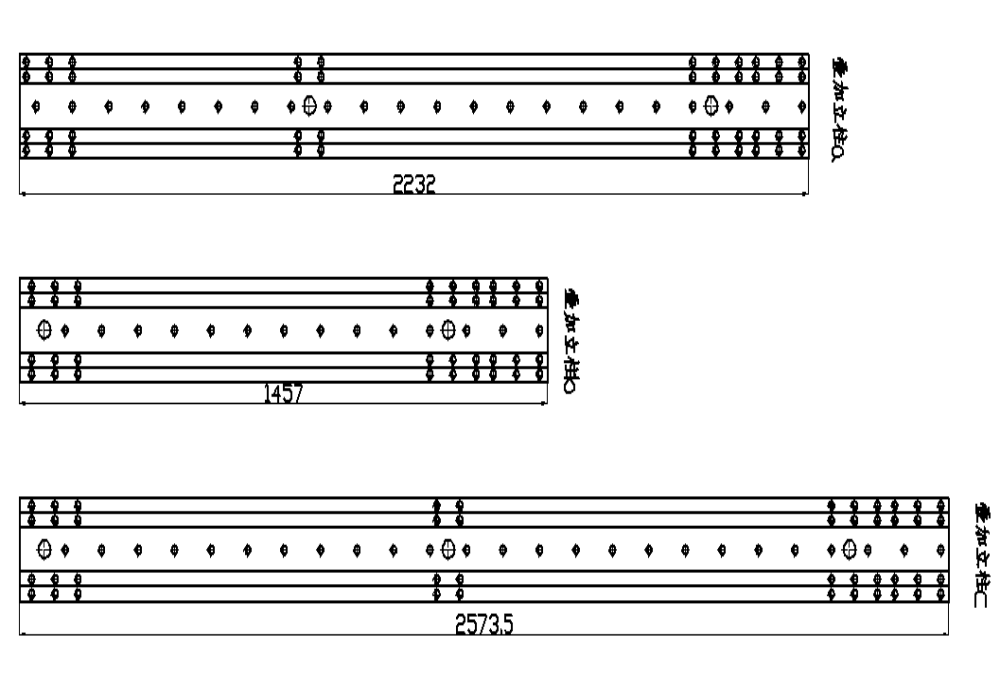

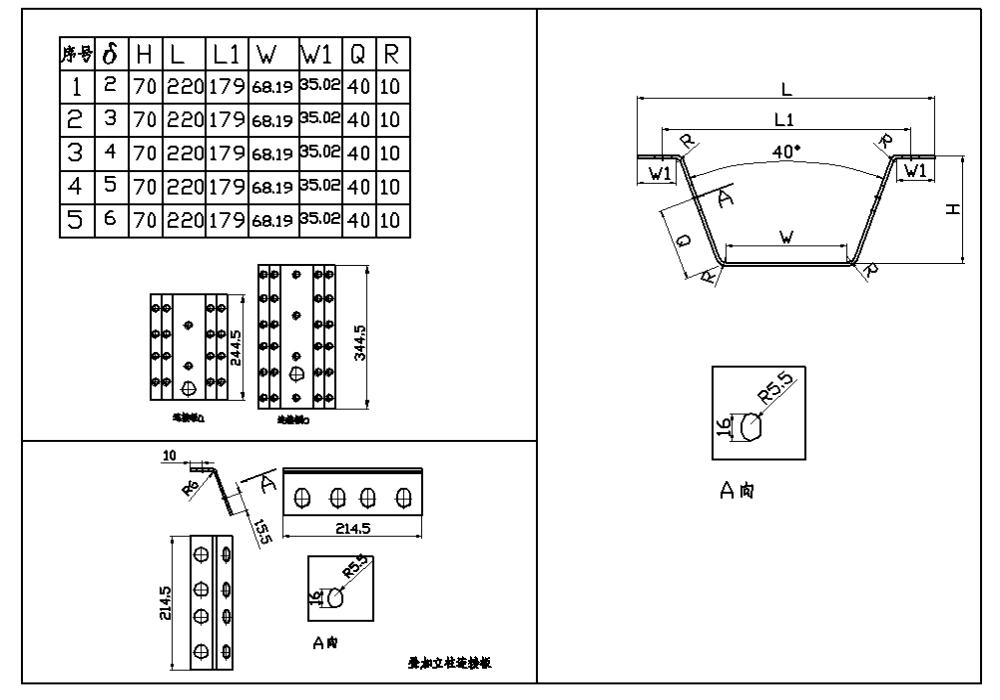

The production flow of equipment

De-coiling—Feeding&leveling—Cutting&welding——Punching——rollforming——Punching——hydraulic cut to length——Auto stacker

10 ton Hydraulic de-coiler with coil car

- Single unrolling machine, one side can put material

- Adopt automatic hydraulic system

- Coil weight (Max):10000kg

- Coil dia (Max):1600mm

- Oil cylinder dia:1200mm working pressure: 10mpa

- Coil Width (Max.):500mm

- Working speed: 10m/min

- Power: 5KW

Main features of the machine:

The leveling roller's mechanical property such as rigidity and roughness concentration of the surface are rising very much after hardening and tempering. It includes pinch roll and leveling roll. The pinch roll can adjust along. The leveling roll uses the whole structure. There are two adjusting point at the front and the end. It can form a certain banked angle to improve the leveling quality. The feeding port of the leveling machine has a pair of guide plain-barrelled roll and two pairs of guide vertical roll. The guide vertical roll can moves centered or moves at the same time. It is adjusted by hand wheel, so it is convenient to centered

1: feeding the sheet to the guide roller (it is adjustable by right and left).

2: feeding roller: diameter is ¢160mm; material is 40CR steel, HRC48-52.

3: Leveling roller: upper is 3 rollers, down is 4 stations(total is 7 stations), material is 40CR steel, HRC48-52.

4: diameter of leveling roller: 180mm

- Using hydraulic punching

- Oil cylinder dia:¢220mm

- Working pressure:18mpa

- Mould material: Cr12mov quenched 58°-62°

- Hydraulicstation power:30kw

- using hydraulic punching

- Pressure: 250 tons

- oil cylinder dia:¢180mm

- working pressure:30mpa

- mould material: Cr12mov quenched 58°-62°

- hydraulicstation power:55kw

- Punching die set: total 3 sets of bottom punching die 5-3.0mm, 3.5-4.5mand 5-6mm

Servo following Cutting

- hydraulic non stop Servo following cutting

- knife material: Cr12mov,quenched 58°-62°

- oil cylinder dia:250mm

- working pressure:60mpa

- working journey: 80mm

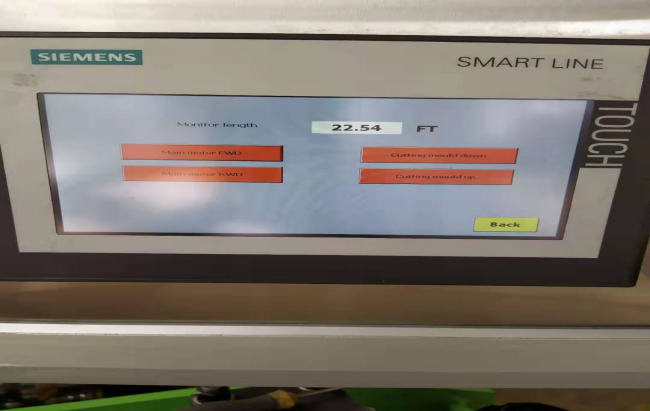

1: Full line is controlled by PLC Siemens, touch Screen Siemens, transducer Siemens or ABB control system touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control) and modify the parameter to control the line. Also can check the running status, parameter and error indication etc..

2: Operation type: manual /auto two type switch. In manual position: can run the each part of the machine. In auto position: can run the full line. The emergency stop ensures the safe of the equipment and operator.

3: Machine side is equipped with the manual operation control panel for convenient worker to operate;

4: Entire line surveillance function: to reach surveillance production line movement condition, realizes to various locations production condition surveillance;

5: Has the failure detection function: Carries on to the production line signal succession examines, the checkup according to sequence, discovers the mistake, and giving the alarm to stop the machine