PPGI Galvanized Metal Sheet Slitting Line Machine

|

NO. |

Name |

Unit |

Parameters |

|

1 |

Control model |

|

Frequency conversion control |

|

2 |

Materials |

|

GI, PPGI, CRS |

|

3 |

Thickness |

mm |

0. 3-1.5 |

|

4 |

Width |

mm |

1250 |

|

5 |

Coil I.D. |

mm |

508 |

|

6 |

Coil O.D. |

mm |

≤1400 |

|

7 |

Weight |

T |

10 |

|

8 |

Slitting blade shaft |

mm |

Φ120 |

|

9 |

Blade specification |

mm |

Φ220×Φ120×10 |

|

10 |

Material of blade |

|

6CrW2Si |

|

11 |

Line speed |

m/min |

≤40 |

|

12 |

Power of decoiler |

KW |

11 |

|

13 |

Power of slitting machine |

KW |

15 |

|

14 |

Power of recoiler |

KW |

30 |

|

15 |

Quantity of strips (Max) |

Strips |

15pcs (0.3mm), 5pcs(1.5mm) |

|

16 |

Width tolerance |

|

≤±0.05 mm |

|

17 |

The direction of whole line |

|

from right to left, the operate table faces the machines |

|

18 |

Power |

|

380V/3Ph/50Hz( Customized) |

|

19 |

Operation people |

|

1 technician and 1 general worker |

|

20 |

Color |

|

green ( Customized) |

|

21 |

Daily production amount |

T |

40 |

|

22 |

Machine weight |

T |

16 |

|

No |

Name |

Quantity |

|

1 |

Hydraulic entry coil car |

1 set |

|

2 |

Hydraulic de-coiler |

1 set |

|

3 |

Slitting machine |

1 set |

|

4 |

Scrap winder |

1 set |

|

5 |

Hydraulic tension stand |

1 set |

|

6 |

Re-coiler |

1set |

|

7 |

Hydraulic exit coil car |

1set |

|

8 |

Hydraulic system |

1 set |

|

9 |

Electrical control system |

1 sets |

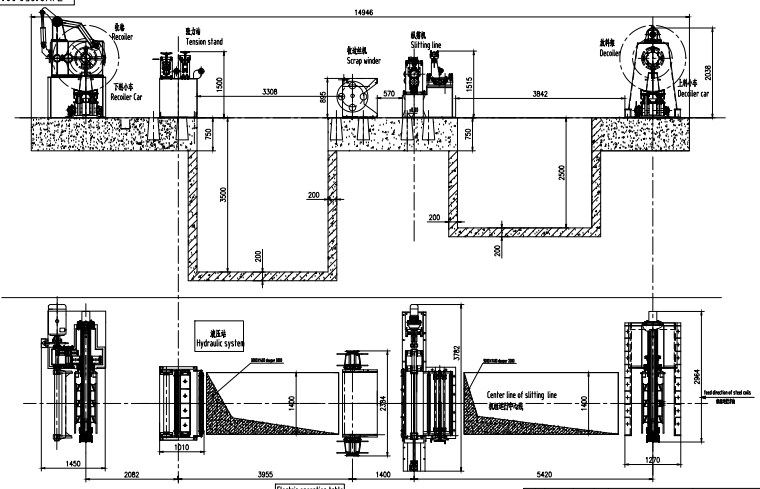

The layout: