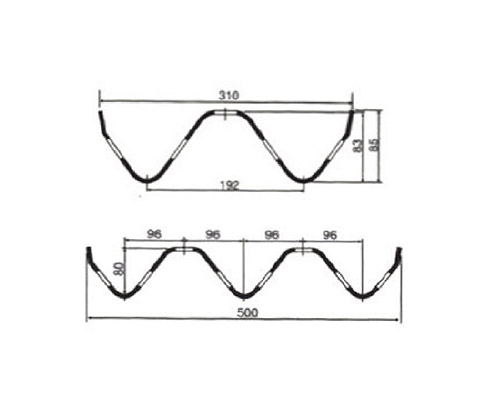

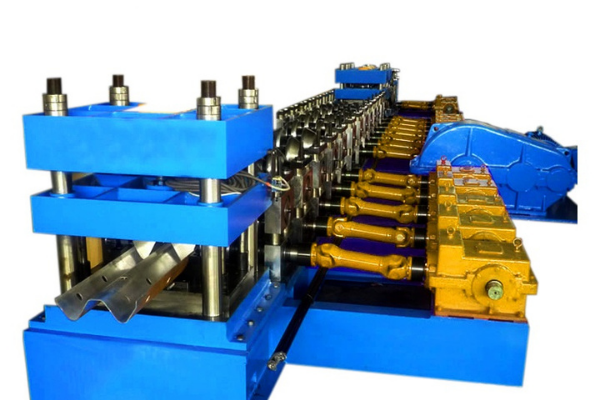

Two Waves Three Waves Guard Railway Roll Forming Machine

Description

Highway guardrai machine can make two waves W beam guardrail, three waves guardrail, also we can design two waves or three waves profiles make in one machine by cassetee, the guardrail’s thickness is usually 2.0mm-4mm, the punching holes can be made by press machine or hydraulic punching to save costs.

We can also produce machine equipment related to guardrail machine, like U/C/sigma post roll forming machine, connection punching line, etc.

Guard Railway Roll Forming Machine Technial Data:

1. Main motor power: 22kw

2. Station: adopt cast iron HT50

3.Decelerating motor: BWD14-43-37KW, made in Shanghai or Changzhou

4. Drive: chain driving

5. Main shaft dia: ¢120mm material: 45﹟forge steel

6. Roller material: GCR15 quenched 58°-62°,chromed

7. Roll station:15stations

8. Roller thickness: 3-5mm

9. Timing by transducer:5m--20m/min(not including punching)

10. Transducer: Panasonic made in Japan. 380V 50HZ

11. Computer: PLC

12. Computer operating panel: touching screen

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

Our display screen is touch screen, not text touch screen.

Sussman roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.

Highway Guard rail or guardrail, sometimes referred to as guide rail or railing, is a system designed to keep people or vehicles from (in most cases unintentionally) straying into dangerous or off-limits areas. A handrail is less restrictive than a guard rail and provides both support and the protective limitation of a boundary.

We can make two waves, three waves for highway guardrail.