Garage Door Support Guide Rail Roll Forming Machine

Shutter door guide rail roll forming machine popular sell in many countries. We ship shutter guide rail roll forming machine all over the world like India, Thailand, Russia, Algeria, Qatar, Morocco, Saudi Arabia, Oman etc. Product thickness common between 0.8mm-2.0mm, material use Galvanized steel.

Technical Data:

|

Items |

Specifications |

|

|

Material of coil |

Material Thickness |

1.5mm-2.0mm galvanized sheet |

|

Punching |

Type |

2 sets of punching mould |

|

Forming system |

Rolling Speed |

About 0-12 meters /minute line speed, with hydraulic punching 2-3 meters/minute |

|

|

Roller Stations |

About 16 stations |

|

|

Roller Material |

Gcr15 Steel with quenching 60mm shaft

|

|

|

Maim Motor Power |

7.5 kw |

|

|

hydraulic station Power |

4 kw |

|

Cutting system |

Material Of Cutting |

CR12 with quench treatment |

|

|

Hardness |

HRC58-62 |

|

|

Tolerance |

+-1.5mm |

|

Electrical control system |

Electric Source |

220V, 60HZ,3 phase Also can satisfy Customer’s require |

|

|

Control System |

PLC control system |

|

|

Weight |

About 5 tons |

|

|

Way Of Drive |

1 inch single chain |

Machine List:

|

3 ton passive de-coiler |

1 set |

|

Hydraulic punching device( with 2 sets of punching mould) |

1 set |

|

Main roll forming machine |

1 set |

|

PLC Control box |

1 unit |

|

6 meters passive output table |

2 units |

|

Hydraulic cutting device |

1 unit |

|

Safety cover |

1 unit |

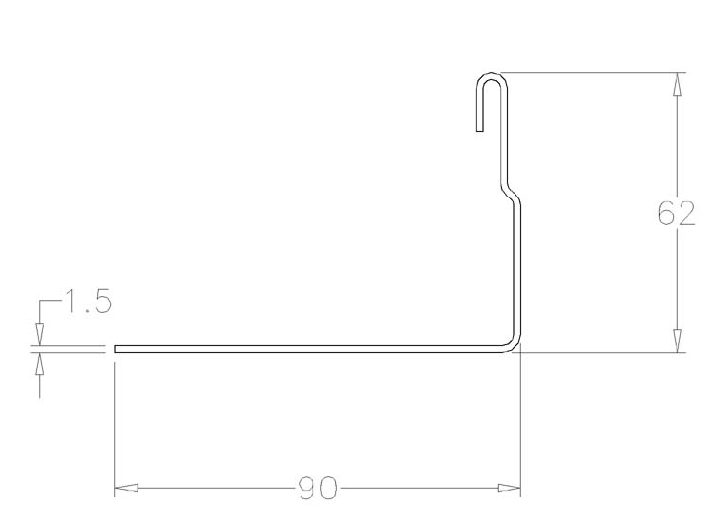

Profile Drawing:

Samples:

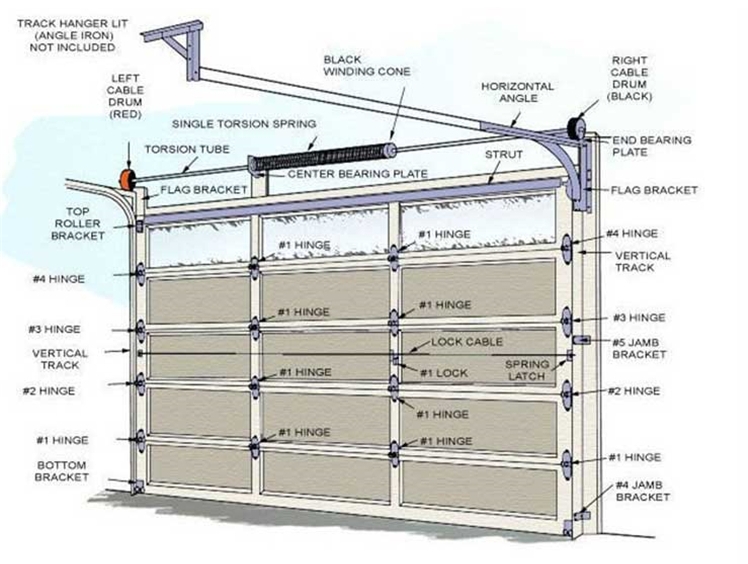

Application: