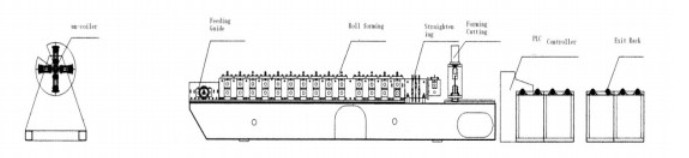

Technological process

- Technical Data

|

Item NO |

Description |

Unit\Type |

RF-RP |

|

1 |

Material Thickness |

mm |

0.7-1.2mm for Color coated steel 0.5-0.8mm for aluminum sheet |

|

2 |

Forming Speed |

m/min |

0-10 |

|

3 |

Roller stands |

stands |

15 |

|

4 |

Roller Material |

|

45# steel, coated with chrome, fire treated, HRC 58-62 |

|

5 |

Shaft diameter and materail |

|

Ф70, 45# steel, fire treated, HRC 58-62 |

|

5 |

Main Motor Power |

Kw |

7.5 |

|

6 |

Hydraulic cutting Power |

Kw |

3 |

|

7 |

Hydraulic pressure |

Mpa |

12 |

|

8 |

Power Supply |

|

According to client’s requiry |

|

9 |

Tolerance |

mm |

1.5 |

|

10 |

Material of cutting |

|

Cr12 |

|

11 |

Control system |

|

PLC with touch screen |

|

12 |

Main machine weight |

T |

6-7 Ton |

|

13 |

Outer specification |

m |

7*1.2*1.2 |

|

14 |

Transmission Type |

|

1 inch chain drive |

Decoiler:

- Type:5 passive tons,

- Range of expansion: 400mm-570mm

Cutting:

(1) Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

(2) Material of blade: CR12mov heat treatment

(3) Length measuring: Automatic length measuring

(4) Tolerance of length: +/- 1.5mm

Control Box: Panasonic Brand

(1) Voltage, Frequency, Phase: 380v, 50 Hz, 3Phase

(2) Automatic length measurement:

(3) Automatic quantity measurement

(4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5) Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7) Unit of length: millimeter (switched on the control panel)