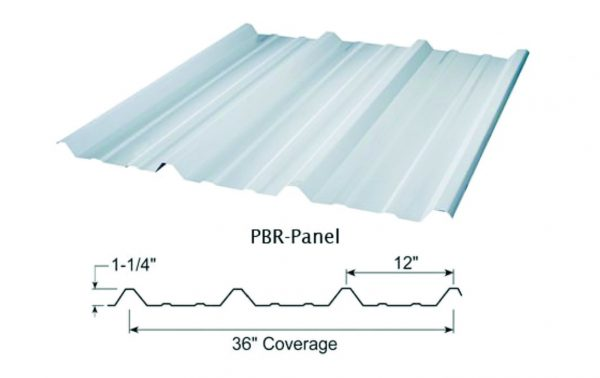

30m/Min High Speed 36″ Wide PBR Panel Roll Forming Machine

This roof machine is to make PBR panel, similar R panel And J rib Panel, this line includes 5 tons hydraulic decoiler, pre-cutting device, plastic film device, roll forming machine part, servo following cutting, and finished products receiving table, also auto stackers for your optional.The normal machinable thickness range of our roof panel roll forming machine is 0.3mm-0.8mm ( 29 gauge- 26 gauge steel)

|

Item NO

|

Description

|

Offered specification

|

|

1.1

|

Rolling speed

|

30 meters/min(not include cutting time)

|

|

1.2

|

Rolling thickness

|

0.3mm-0.8mm

|

|

1.3

|

Raw material

|

Color painted coils, Aluminium, Zinc, Galvanized

|

|

1.4

|

Main Motor

|

7.5KW*2

|

|

1.5

|

Dimension

|

About 11000×1600×1200(mm)

|

|

1.7

|

Roller stations

|

About 20-22 stations

|

|

1.8

|

Roller material

|

45#forge steel, coated with chrome

|

|

1.9

|

Shaft diameter

|

Φ76mm

|

|

1.10

|

Transmission

|

By chain 1.2 inch

|

|

1.11

|

Material of chain

|

45# forged steel with frequency quenching, 12A

|

|

1.12

|

Material of cutting

|

Cr12Mov with quench HRC58-62°

|

|

1.13

|

Tolerance

|

10m+-1.5mm

|

|

1.14

|

Hydraulic station

|

5.5kw

|

|

Machine list |

5 tons de-coiler and coil car with arm device |

1 set |

|

|

Feeding with guide |

1 set |

|

|

Main roll forming machine |

1 set |

|

|

Servo following cutting |

1 set |

|

|

Extra cutting blade |

1 set |

|

|

Control box |

1 unit |

|

|

Hydraulic station |

1 unit |

|

|

Safety cover |

1 set |

|

|

Spare parts |

1 package |

PBR panels are 26-gauge steel and 1-1/4” rib height

A PBR Panel, in the context of construction and roofing, refers to a type of metal roofing panel that is commonly used in commercial, industrial, and agricultural buildings. "PBR" stands for "Purlin Bearing Rib," indicating its design and function in relation to roof purlins.

Key characteristics of a PBR Panel include:

-

High Rib Profile: PBR Panels have a high rib profile with deep, wide ribs that provide strength and structural stability to the roofing system. These ribs contribute to the panel's ability to span across purlins or supports without the need for solid decking.

-

Purlin Bearing Design: The term "Purlin Bearing" suggests that the panels are designed to rest on and be fastened directly to roof purlins. Purlins are horizontal support members typically installed on the roof structure.

-

Weather Resistance: PBR Panels are known for their weather resistance and durability. They are often made of galvanized steel or other metal materials with protective coatings, making them suitable for withstanding various weather conditions.

-

Wide Coverage: PBR Panels typically have a wide coverage area, which means that fewer panels are needed to cover a given roof area, contributing to faster installation and cost-effectiveness.

-

Ease of Installation: Due to their design and the ability to span across purlins, PBR Panels are relatively easy to install. The panels are often available in various lengths, allowing for flexibility in accommodating different roof designs.

-

Variety of Finishes: PBR Panels are available in a variety of finishes and colors, providing aesthetic flexibility for different architectural preferences.

PBR Panels find wide application in the construction industry, particularly for roofing on commercial, industrial, and agricultural buildings. The design and features of PBR Panels make them well-suited for various applications:

-

Commercial Buildings: PBR Panels are commonly used for roofing on commercial structures such as retail stores, offices, shopping centers, and other non-residential buildings. Their durability and ease of installation make them a practical choice for commercial applications.

-

Industrial Facilities: PBR Panels are widely employed in industrial settings, including warehouses, manufacturing plants, and distribution centers. The high rib profile and purlin-bearing design contribute to their strength and load-bearing capacity, making them suitable for large industrial roofs.

-

Agricultural Buildings: Farms and agricultural structures often utilize PBR Panels for their roofing needs. These panels are durable and can withstand the often harsh conditions associated with agricultural environments.

-

Self-Storage Facilities: PBR Panels are commonly used in the construction of self-storage buildings. Their wide coverage, weather resistance, and straightforward installation make them a practical choice for such facilities.

-

Arenas and Sports Facilities: The versatility and structural strength of PBR Panels make them suitable for the roofing of arenas, sports complexes, and recreational facilities.

-

Utility and Storage Sheds: PBR Panels are often chosen for utility buildings, storage sheds, and similar structures due to their cost-effectiveness, durability, and ease of installation.

-

Educational Institutions: Some educational institutions, especially those with large facilities like gymnasiums or auditoriums, may use PBR Panels for their roofing needs.

-

Renovations and Retrofits: PBR Panels can be used in renovation projects or as part of retrofitting existing structures. Their flexibility in design and ease of installation make them suitable for upgrading older buildings.

It's important to note that while PBR Panels are versatile and widely used, the specific application can depend on factors such as local building codes, climate conditions, and the requirements of the particular structure. Additionally, PBR Panels can be used not only for roofing but also for siding applications, providing a cohesive appearance for the entire building envelope.