Round Downspout Tube Roll Forming Machine – The Ultimate Solution for Efficient Rainwater Drainage Systems

03 Jun

.jpg)

Round Downspout Tube Roll Forming Machine – The Ultimate Solution for Efficient Rainwater Drainage Systems

Introduction

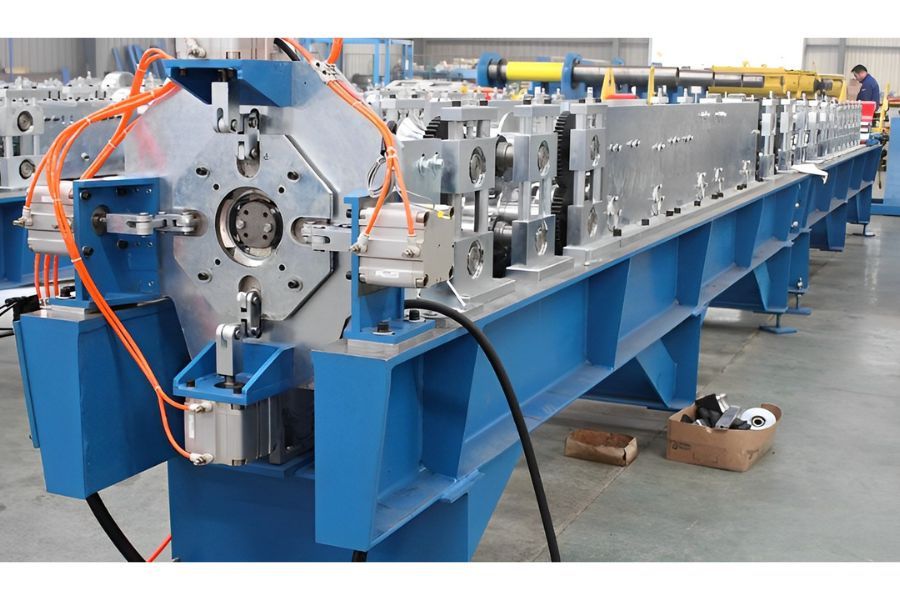

In modern construction, round downspout tubes play a critical role in effective rainwater drainage, ensuring buildings remain protected from water damage. The Round Downspout Tube Roll Forming Machine is the advanced equipment behind the production of these essential components, offering precision, speed, and cost-efficiency in manufacturing.

This blog explores:

✔ What is a Round Downspout Tube Roll Forming Machine?

✔ Key features and benefits

✔ Applications of round downspout tubes

✔ Why investing in this machine is a smart business decision

What is a Round Downspout Tube Roll Forming Machine?

A Round Downspout Tube Roll Forming Machine is an automated production line that transforms metal coils (galvanized steel, aluminum, or copper) into seamless, high-quality round downspout tubes. The machine uses a series of rollers to gradually shape flat metal strips into perfectly round tubes with consistent diameter, smooth finishes, and excellent durability.

Key Features of Round Downspout Tube Roll Forming Machines

1. High-Speed Production

✔ 10-12 meters per minute output for large-scale projects

✔ Reduces labor costs with fully automated operation

2. Precision Engineering

✔ CNC-controlled for exact diameter (±0.2mm tolerance)

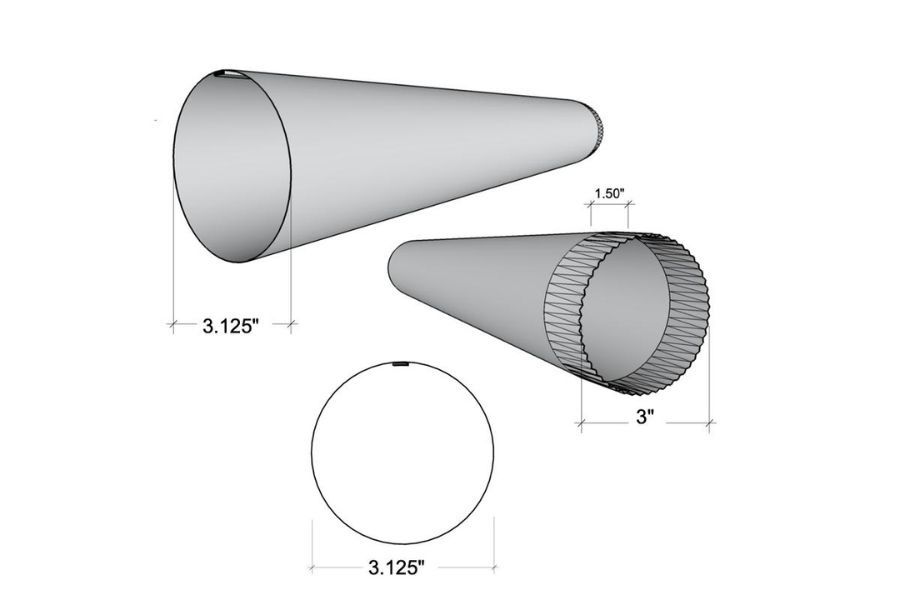

✔ Adjustable rollers for different tube sizes (3" to 6" diameters)

3. Material Versatility

✔ Processes galvanized steel (0.4-1.0mm), aluminum (0.5-1.2mm)

✔ Handles pre-painted or plain metal coils

4. Customization Options

✔ Produces standard 3", 4", and 5" diameter tubes

✔ Custom sizes and decorative patterns available

5. Low Maintenance & Durability

✔ Hardened steel rollers for long-lasting performance

✔ Easy-to-replace parts minimize downtime

Applications of Round Downspout Tubes

1. Residential Buildings

✔ Homes and villas requiring efficient drainage

✔ Historic restorations needing period-accurate designs

2. Commercial & Industrial Properties

✔ Office buildings with high rainwater runoff

✔ Warehouses and factories needing durable systems

3. Architectural & Decorative Use

✔ Luxury buildings with copper downspouts

✔ Custom-colored tubes for aesthetic appeal

4. Agricultural & Municipal Use

✔ Barns and greenhouses requiring corrosion-resistant drainage

✔ Public infrastructure like bus stops and walkways

Why Invest in a Round Downspout Tube Roll Forming Machine?

✅ High Demand – Growing need for efficient drainage solutions

✅ Profitability – Custom tube production for contractors & wholesalers

✅ Energy Efficiency – Low power consumption with high output

✅ Future-Proof Business – Sustainable metal products market

Conclusion

The Round Downspout Tube Roll Forming Machine is revolutionizing rainwater management by enabling fast, precise, and cost-effective production of durable downspout tubes. Whether for residential, commercial, or industrial use, this machine ensures high-quality output with minimal waste.

Interested in adding this technology to your production line? Contact us today for expert consultation!