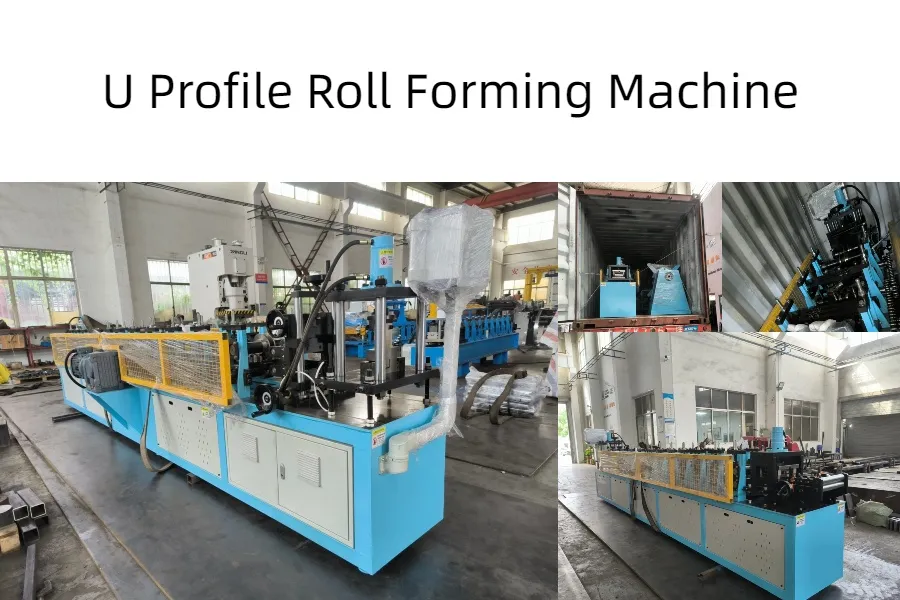

Precision and Power: U Profile Roll Forming Machine Loaded for Mexico on July 11

12 Jul

On the morning of July 11, a state-of-the-art U profile roll forming machine was loaded at our factory and dispatched to Shanghai Port for shipping to Mexico. This equipment is a testament to our company’s dedication to manufacturing high-performance, customized machinery that meets the diverse needs of international markets. Featuring multi-size forming capabilities and an integrated hydraulic punching system, this machine promises to enhance our client's production efficiency while expanding their product range.

Custom Roll Forming for Modern Needs

This U profile roll forming machine is not a one-size-fits-all piece of equipment—it is designed to manufacture a range of U profile sizes, which makes it suitable for companies involved in the production of metal channels used in drywall systems, cable management, metal framing, and various industrial frameworks.

The flexibility of this roll former lies in its adjustable tooling system. Changing the size of the U profile is a straightforward process, supported by digital controls and easily interchangeable dies. The user can quickly switch between different dimensions, ensuring minimal downtime between production runs.

This adaptability significantly reduces the need for multiple machines or manual labor, thereby optimizing space and workforce allocation in the factory.

Seamless Hydraulic Punching Integration

Unlike conventional systems that require a separate punching machine, this model features a built-in hydraulic punching station on the main roll forming line. As the metal coil feeds through the forming section, the hydraulic punching unit performs high-speed, high-precision perforations directly on the running sheet. This results in a continuous and streamlined workflow from raw material to finished product.

The hydraulic punching system is synchronized with the roll forming line using a PLC-based control system, which guarantees exact punching locations and allows the user to set different punching patterns or hole sizes according to specific job requirements.

Such automation significantly enhances accuracy while reducing waste and manual rework, making it a valuable asset for factories focusing on high-volume or customized production.

Reliable and Responsible Shipping Process

Preparing the machine for overseas shipment involved a thorough testing phase to confirm all electrical, mechanical, and hydraulic components were operating flawlessly. Once validated, the machine components were securely wrapped, labeled, and arranged inside a steel container for maritime transport.

Our logistics team followed international shipping standards to ensure that every part—including the roll forming base, punching unit, motorized decoiler, control panel, and spare parts—was protected from moisture, impact, and movement during the long voyage to Mexico.

The loaded container was dispatched from our factory on the same day and is expected to arrive at the Shanghai Port shortly, where it will be loaded onto a vessel bound for Latin America.

A Growing Presence in Latin America

Mexico is a rapidly growing hub for metal building products, and we are proud to contribute to this growth with our high-quality roll forming machinery. With the rising demand for prefabricated structures and modern construction solutions, machines like the U profile roll former are becoming increasingly essential.

This shipment reflects not only our growing reputation in the region but also our ability to design and deliver tailored solutions across borders. It is worth noting that this is not our first machine delivered to Mexico—several clients have previously chosen our equipment for roofing, drywall, and structural profile production.

We maintain long-term relationships with our clients by offering remote troubleshooting, virtual training, and fast spare part delivery, ensuring that their machines remain in excellent working condition for years to come.

As this U profile roll forming machine makes its journey to a new home in Mexico, we remain committed to supporting our customer’s goals with reliable technology and professional service. We are confident that this investment will help them achieve greater efficiency, versatility, and profitability in their production line.