Mexico Popular Warehouse Roof Wall Ceiling----Bset Choice

14 Nov

Best Choice for Warehouse Roof Wall Ceiling Panel---100/35 Popular in Mexico

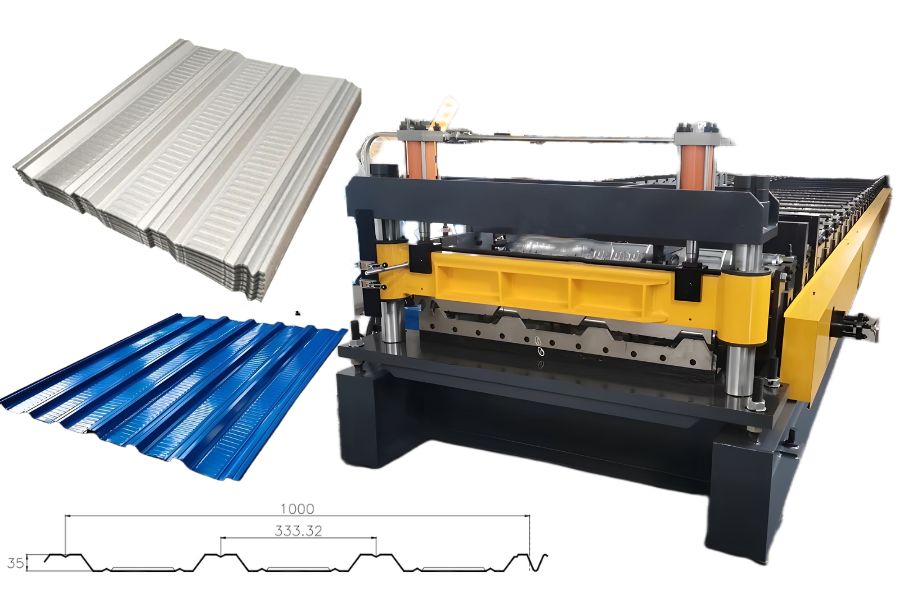

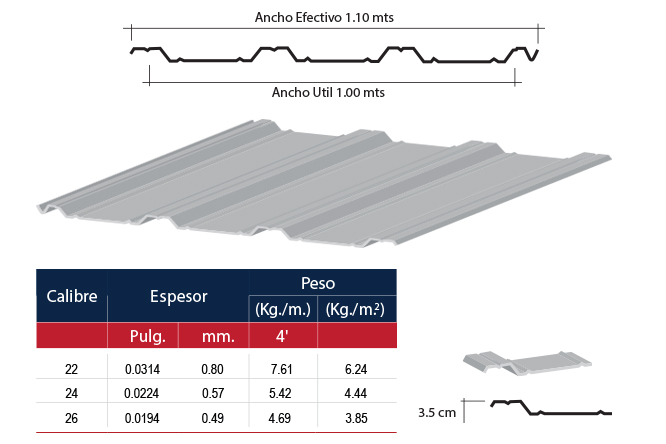

The 100/35 roof panel typically refers to a profiled metal roofing panel with a specific thickness and rib height used primarily in commercial, industrial, and residential construction. Here’s what the numbers generally mean:

- 100: This refers to the width of the panel (in millimeters), typically indicating the distance between two adjacent ribs. In this case, the panel has a 100 mm wide section between the ribs.

- 35: This refers to the height of the rib (in millimeters). The panel has a 35 mm rib height, which provides structural strength and water drainage properties.

Key Features of the 100/35 Roof Panel

1. Profile and Design

- Profiled Design: The 100/35 roof panel has a corrugated or ribbed profile, where the ribs (or corrugations) help provide structural strength, rigidity, and enhanced water runoff. The 100 mm width between ribs and 35 mm rib height give it a distinctive appearance, with a balance of strength and flexibility.

- Materials: These panels are usually made from steel (galvanized or color-coated steel) or aluminum, which offers excellent durability, corrosion resistance, and weather resistance. The steel used in the panels is often treated with a coating like Zinc-Aluminum (Zincalume), PVC, or Polyester to enhance longevity and corrosion resistance.

2. Applications

- Roofing: As a roofing solution, 100/35 panels are commonly used for industrial, commercial, and agricultural buildings, where their corrugated profile ensures good water runoff and stability against wind loads. They are often used in factories, warehouses, sheds, and agricultural barns.

- Wall Cladding: These panels can also be used for wall cladding, thanks to their strength and aesthetic appeal. The 100/35 profile provides a robust and visually appealing surface for external walls in both industrial and residential buildings.

- Residential: While more common in commercial and industrial applications, some modern homes and outbuildings (like garages or garden sheds) may also use 100/35 panels for roofing.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg)

.jpg)

3. Strength and Durability

- Structural Strength: The ribbed design, with a 35 mm rib height, provides good strength, allowing the panel to withstand the weight of snow, rain, or other environmental forces. The steel construction adds to the overall durability, ensuring the roof can handle the load and stresses from the environment.

- Weather Resistance: The 100/35 roof panel is designed to resist adverse weather conditions like heavy rainfall, strong winds, and snow. The panels are also resistant to corrosion, especially if they are coated with protective layers, making them suitable for use in coastal and harsh environments.

- Long Lifespan: These panels are often designed to last 25 years or more, depending on the environment and maintenance. Coatings like Galvanization or Aluzinc can extend the panel's lifespan by preventing rust and corrosion.

4. Thermal Insulation

- Energy Efficiency: While the 100/35 profile itself is primarily designed for strength and weather resistance, it can be combined with additional insulation layers, such as polyurethane (PU), polystyrene, or mineral wool for improved thermal performance. This is especially useful in buildings that need to maintain a specific internal temperature or reduce heating/cooling costs.

- Reflective Coatings: Some versions of the 100/35 panels come with reflective coatings that help reduce heat absorption, making them more energy-efficient in hot climates.

5. Ease of Installation

- Pre-Fabricated: These panels are usually prefabricated, meaning they come ready to be installed with minimal processing on-site. This allows for faster construction times.

- Lightweight: Steel panels are relatively lightweight, making them easier to handle and install compared to traditional materials like concrete tiles or clay roofing.

- Interlocking: Many 100/35 panels come with an interlocking design, which helps speed up installation while providing better protection against wind uplift and water ingress.

6. Cost-Effectiveness

- Affordable: Compared to other roofing options like concrete tiles or high-end metal roofing, the 100/35 profile can be more affordable, especially when factoring in its durability, ease of installation, and low maintenance requirements.

- Minimal Maintenance: These roof panels require minimal maintenance. Occasional cleaning and inspection for damage (e.g., dents, rust, etc.) are usually enough to keep the roof in good condition.

7. Aesthetic and Design Flexibility

- Color Options: The panels are available in a wide range of colors, often with polyester, PVDF, or cool roof coatings. This allows them to match the building’s exterior design and enhances their curb appeal.

- Smooth or Textured Finish: The exterior surface can be finished with various textures (e.g., smooth, embossed, or matte), giving the roof panels a variety of design options to suit both functional and aesthetic needs.

8. Sustainability

- Recyclability: Steel is a highly recyclable material, and many 100/35 panels are made from recycled steel. This makes them an environmentally-friendly option.

- Energy-Efficient: When used with appropriate insulation, these panels can contribute to the energy efficiency of the building, reducing reliance on heating or cooling systems.

Conclusion

The 100/35 roof panel is a durable, cost-effective, and versatile roofing solution used in a variety of commercial, industrial, and residential applications. With its combination of strength, weather resistance, and ease of installation, it’s a popular choice for buildings requiring a reliable and efficient roofing system. Whether used in warehouses, industrial facilities, or agricultural buildings, the 100/35 panel offers long-lasting performance and excellent protection against the elements. If you're considering this for your project, make sure to assess the specific needs for insulation, water drainage, and wind resistance in your area.