Industrial Plants And Warehouses

13 Jun

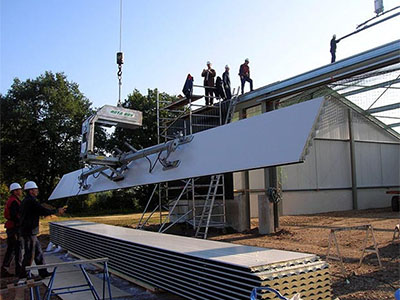

Sandwich panels are assembled roof and wall elements that have excellent insulating characteristics thanks to the integration of insulating material. They consist of two thin metal cover sheets, which are shear-resistant and are bonded to one another on an insulated core. The insulated cores normally consist of rigid polyurethane foam , expanded polystyrene foam, phenolic foam, cellular glass and mineral wool (MW) as well in order to meet the fire prevention requirements. Sandwich panels are produced by discontinuously or continuously running production processes and cut to ordered lengths. The surfaces can also exist of lined, trapezoidal or corrugated profiles, depending on the customer's requirements.

Sandwich panels due to their physical, mechanical and design properties are available for a variety of applications: roof and wall, ceiling . They are used in industry and in residential sector, and the two sectors can be used in both new construction and rehabilitation. Some of the applications where we can find sandwich panels are:

• Industrial buildings

• Public buildings

• Offices and administration buildings

• Cold storages

• Clean rooms

• Agricultural buildings

• Power plants

• Residential houses

Related Products

PU continuous sandwich panel roll forming machine

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor27 Aug

Fly Cut Roof Panel Machine

19 Aug

Ladder Cable Tray Machine

19 Aug

Boltless Roof Panel Machine18 Aug

Upright Racking Machine

18 Aug

Shutter Guide Rail Machine