Indonesia Ladder Cable Tray Systems – The Complete Guide to W-Shape and U-Shape Solutions

06 Aug

Indonesia Ladder Cable Tray Systems – The Complete Guide to W-Shape and U-Shape Solutions

Introduction

In Indonesia's rapidly growing industrial and construction sectors, ladder cable tray systems have become the backbone of efficient cable management. These robust support systems are specifically designed to handle heavy electrical loads while withstanding tropical climate conditions. Among the various designs available, W-shape and U-shape ladder cable trays dominate the market due to their structural advantages and installation flexibility.

This comprehensive guide explores:

✔ Key differences between W-shape and U-shape ladder cable trays

✔ Material specifications for Indonesian applications

✔ Compliance with SNI (Indonesian National Standards)

✔ Installation best practices for tropical environments

W-Shape vs U-Shape Ladder Cable Trays: Structural Comparison

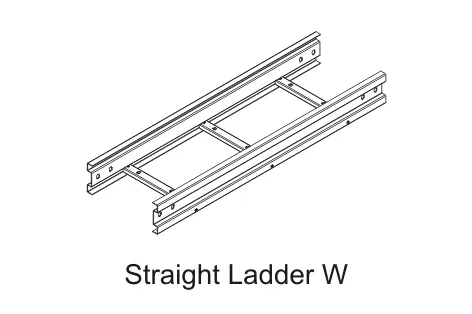

W-Shape Ladder Cable Trays

-

Design Features:

-

Triple-ribbed longitudinal side rails (W-profile)

-

Deeper channel design (typically 50-150mm)

-

Higher load-bearing capacity

-

-

Advantages:

-

30% stronger than U-shape for equivalent material weight

-

Better resistance to side-load forces

-

Preferred for heavy industrial applications

-

-

Common Applications:

-

Power plants and refineries

-

High-voltage cable runs

-

Long-span installations (>3m between supports)

-

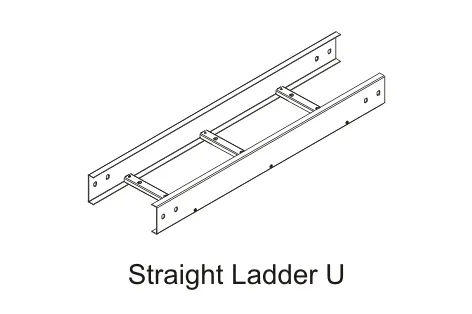

U-Shape Ladder Cable Trays

-

Design Features:

-

Single-curved side rails (U-profile)

-

Shallower profile (typically 30-100mm)

-

Lighter weight construction

-

-

Advantages:

-

20% more material-efficient than W-shape

-

Easier to cut and modify on-site

-

Lower installation costs

-

-

Common Applications:

-

Commercial building wiring

-

Telecom and data centers

-

Short-to-medium span installations

-

Material Specifications for Indonesian Conditions

| Parameter | Galvanized Steel | Stainless Steel 304 | Aluminum |

|---|---|---|---|

| Thickness Range | 1.2-2.0mm | 1.0-2.0mm | 1.5-3.0mm |

| Corrosion Resistance | Moderate (zinc coating) | Excellent | Good |

| Load Capacity | High | Medium | Medium-High |

| Best For | Industrial plants | Coastal areas | Lightweight needs |

Installation Considerations for Tropical Climates

1. Support Spacing Guidelines

-

W-shape: 3-4m spans (up to 6m for heavy-duty)

-

U-shape: 2-3m spans (up to 4.5m with reinforcement)

2. Expansion Joints

-

Required every 30-40m to accommodate thermal movement

-

Critical in areas with high temperature fluctuations

3. Ventilation Requirements

-

Maintain minimum 25% open area for heat dissipation

-

Increase to 40% in high-temperature environments

4. Seismic Considerations

-

Follow SNI 1726:2019 for earthquake-resistant bracing

-

Use flexible couplings in high-risk zones

Conclusion

Choosing between W-shape and U-shape ladder cable trays in Indonesia requires careful consideration of load requirements, environmental conditions, and project budgets. While W-shape offers superior strength for heavy industrial use, U-shape provides cost-effective solutions for commercial applications. Both designs play crucial roles in Indonesia's infrastructure development when properly specified and installed.

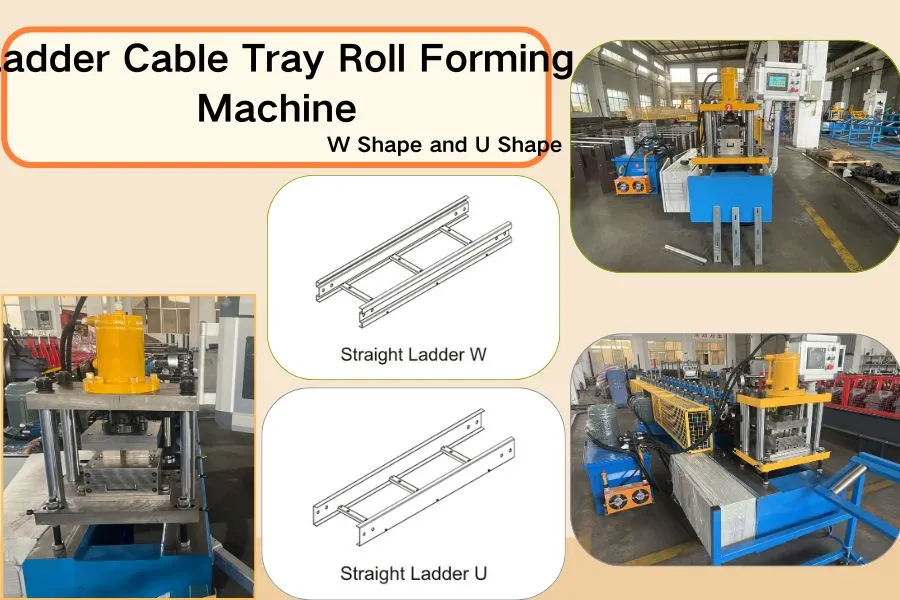

If you need the roll forming machines, please contact us..webp)

.webp)

.webp)