Designing and Installing Metal Fencing Systems – Posts, Rails, and Panels for Australian Properties

12 Jul

Designing and Installing Metal Fencing Systems – Posts, Rails, and Panels for Australian Properties

Introduction

A well-designed metal fencing system requires careful consideration of posts, rails, and panels to ensure structural integrity, security, and visual harmony. In Australia's variable climate, proper material selection, installation techniques, and maintenance are crucial for long-term performance.

This practical guide covers:

✔ Engineering principles for fence stability

✔ Step-by-step installation best practices

✔ Design trends in metal fencing

✔ Maintenance for maximum lifespan

Engineering Principles for Stable Fencing

1. Post Spacing Calculations

-

Standard spacing: 2.4-3.0m between posts

-

Factors affecting spacing:

-

Panel weight and wind load

-

Soil type and foundation

-

Fence height

-

2. Load Considerations

-

Wind load: AS/NZS 1170.2 requirements

-

Impact resistance: AS 4687 for security fences

-

Thermal expansion: Allow 2-3mm gap per meter

3. Foundation Types

-

Concrete footings: 300x300x600mm for standard posts

-

Ground spikes: For temporary or lightweight fences

-

Bolt-down bases: For hard surface installation

Roll Forming Machines: The Backbone of Fence Production

Machine Capabilities

-

High-speed production: 15-30 meters per minute output

-

Precision tolerances: ±0.2mm accuracy for consistent profiles

-

Multi-station forming: 12-18 roller stations for complex shapes

-

Automated cutting: Hydraulic or servo systems for clean edges

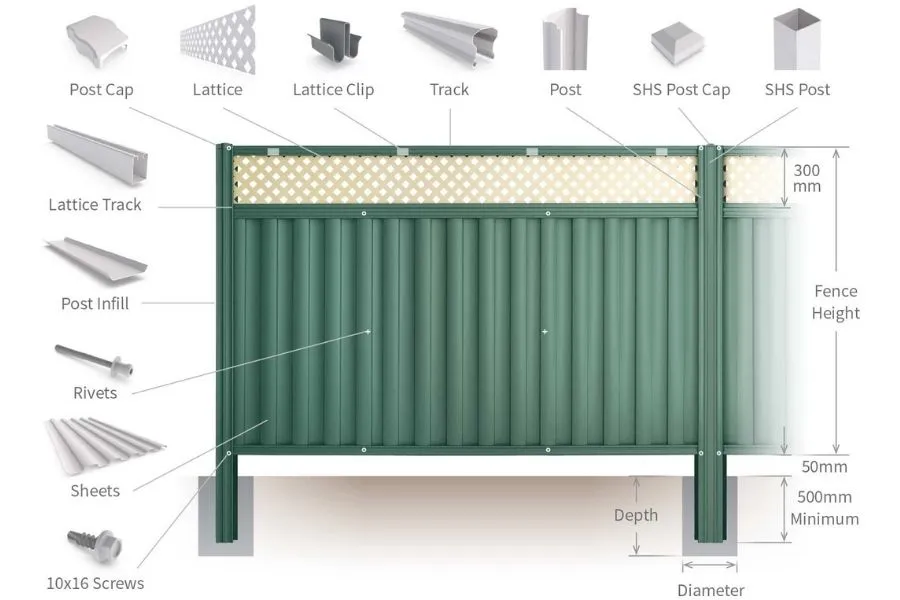

Fence Component Production

-

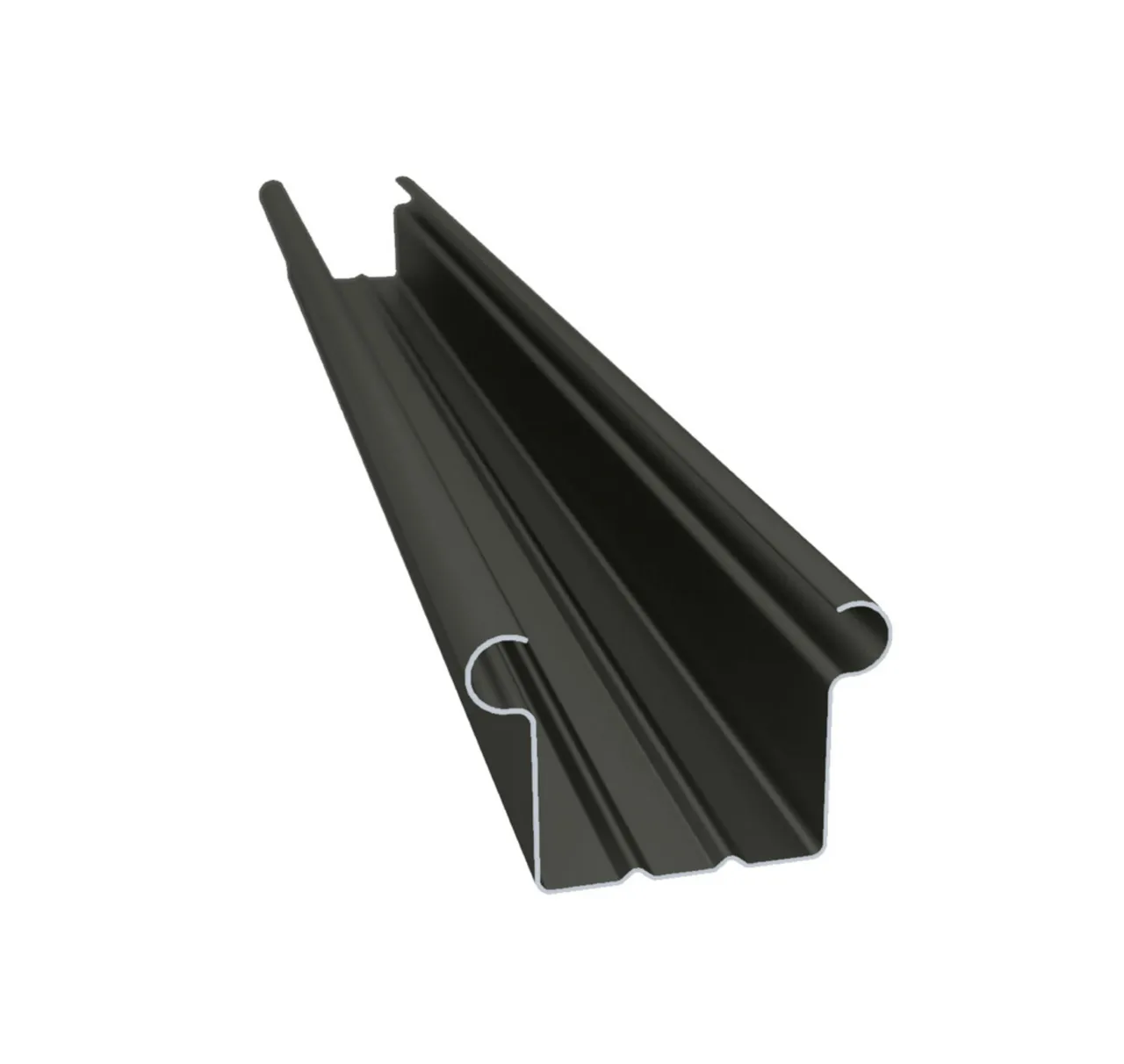

Fence Posts

-

C-channel or square profiles

-

Pre-punched holes for rail attachment

-

Galvanized or powder-coated finishes

-

-

Fence Rails

-

Z-shape or rectangular hollow sections

-

Anti-sag designs for long spans

-

Compatible with various panel types

-

-

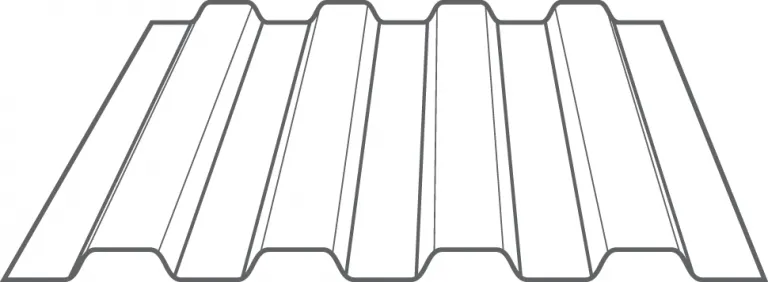

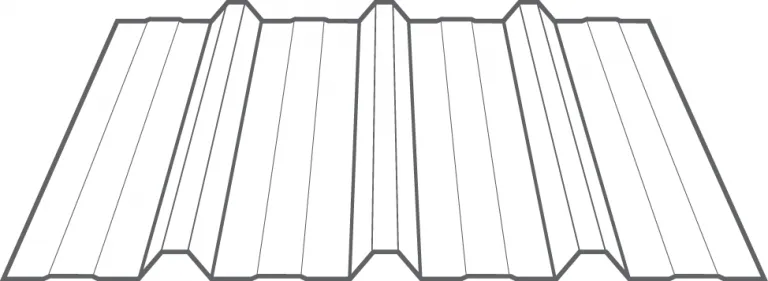

Fence Panels

-

Privacy, semi-private, or ornamental designs

-

Laser-cut patterns available

-

Colorbond® or custom color options

-

Installation Best Practices

Step 1: Site Preparation

-

Check for underground services

-

Mark post locations with string lines

-

Excavate post holes (minimum 600mm deep)

Step 2: Post Installation

-

Set posts in concrete (80mm clearance above ground)

-

Use spirit levels for perfect vertical alignment

-

Allow 48 hours for concrete to cure

Step 3: Rail Attachment

-

Pre-drill rails to match post holes

-

Use galvanized or stainless steel fasteners

-

Maintain consistent height across spans

Step 4: Panel Mounting

-

Start from one end and work sequentially

-

Use rubber spacers to prevent metal-on-metal contact

-

Check alignment after every 3 panels

Design Trends in Australian Metal Fencing

1. Contemporary Styles

-

Horizontal slat fencing

-

Mixed-material designs (metal + timber)

-

Laser-cut decorative panels

2. Color Innovations

-

Two-tone combinations (e.g., Monument® with Surf Mist®)

-

Textured finishes (hammered, brushed)

-

Custom color matching

3. Smart Integration

-

Lighting-ready posts

-

Hidden wiring channels

-

Gate automation compatibility

Maintenance Guide

Annual Checklist

-

Inspect for loose fasteners

-

Check for corrosion or coating damage

-

Clean with mild detergent and soft brush

-

Lubricate gate hinges and locks

5-Year Maintenance

-

Re-tighten all connections

-

Touch up any paint damage

-

Re-seal concrete footings if cracked

Common Issues and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Sagging rails | Excessive span | Install intermediate posts |

| Loose panels | Wind vibration | Add anti-rattle clips |

| White rust | Coastal moisture | Apply zinc-rich paint |

Case Study: Coastal Property Fence

Location: Sunshine Coast QLD

Challenges: Salt spray + high winds

Solution:

-

2.4m aluminum slat fence

-

Marine-grade powder coating

-

Reinforced concrete footings

Results:

✔ 10-year warranty against corrosion

✔ Withstood Category 2 cyclone

✔ Maintained appearance after 5 years

Conclusion

Properly designed and installed metal fencing systems using precision-formed posts, rails, and panels provide Australian properties with security, privacy, and curb appeal that lasts decades. By following engineering best practices and regular maintenance, these fences withstand harsh weather while maintaining their aesthetic value.