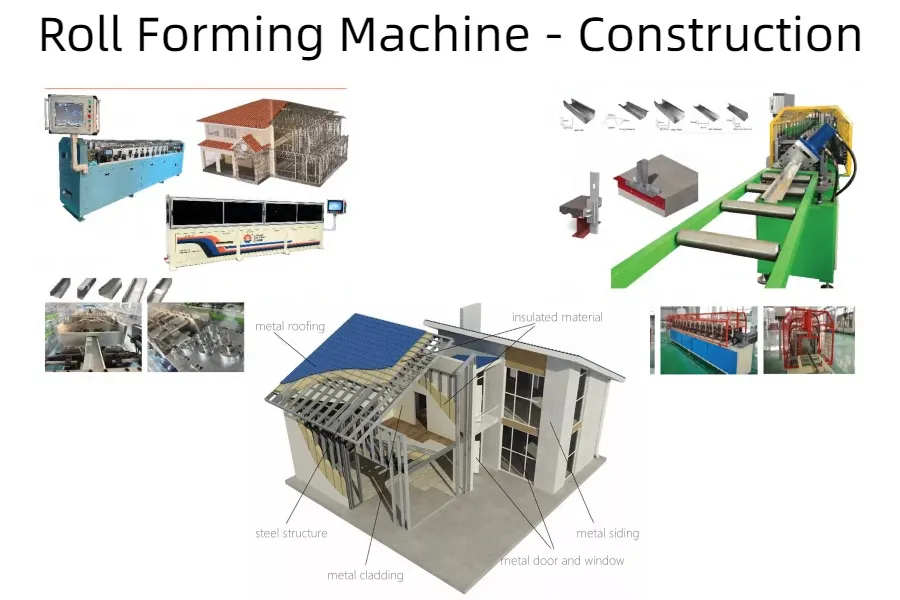

Cold Roll Forming Machines in Residential and Warehouse Construction

20 Aug

In the world of modern construction, efficiency and durability are no longer optional—they are requirements. Residential housing developers and warehouse builders are increasingly turning to cold roll forming machines to meet these demands. These machines transform steel coils into precision-engineered building components that can be quickly assembled on-site. But what specific machines are required, and how are their products used during construction? Let’s take a closer look.

1. Machines for Structural Framework

At the core of every building is its frame, and roll forming machines produce the essential members of this structure.

-

Light Gauge Steel Framing Machines manufacture studs and tracks that form the skeleton of residential walls, floors, and roofs. These profiles are light yet strong, often pre-punched with holes for electrical and plumbing installations. They are connected on-site using self-drilling screws, making assembly as straightforward as piecing together a modular kit.

-

C Purlin and Z Purlin Machines are indispensable for warehouses. The purlins produced support roof sheets and wall cladding. They span large distances, reducing the number of supporting columns needed and lowering construction costs. Installation is simple: purlins are bolted horizontally between main steel beams, creating a sturdy grid for the roof and wall panels.

2. Machines for Roofing Systems

The roof is a building’s shield, and cold roll forming machines provide different solutions depending on the project type.

-

Roof Sheet Roll Forming Machines produce trapezoidal, corrugated, or custom profiles commonly used in both houses and warehouses. These panels are fixed onto the purlins with screws and sealing washers.

-

Standing Seam Roof Machines cater to higher-end residential projects or modern warehouse roofs where watertight performance is essential. The panels are installed with concealed clips and joined with a seaming machine, ensuring no fasteners penetrate the sheet. This results in a sleek, leak-free roof.

3. Machines for Flooring and Decking

For multi-level houses or warehouses with mezzanine floors, Floor Deck Roll Forming Machines provide profiled sheets that act as a permanent formwork. Once laid over beams and topped with concrete, they create strong composite slabs that resist heavy loads.

4. Machines for Walls and Interiors

Walls are more than just barriers; they provide insulation and aesthetics.

-

Wall Panel Roll Forming Machines produce steel cladding sheets or sandwich panels, used as exterior skins for warehouses. These panels are directly screwed to purlins.

-

Stud and Track Machines are widely used in residential interiors. They produce smaller profiles that form partitions and ceilings. Drywall or plasterboard is screwed onto these frames to create smooth, finished walls.

5. Machines for Drainage and Accessories

Every building must handle water efficiently.

-

Gutter Roll Forming Machines produce eaves gutters that collect rainwater.

-

Downspout Roll Forming Machines create vertical pipes that guide water away from the structure.

-

Ridge Cap and Flashing Machines manufacture finishing trims to seal joints at ridges, corners, and edges.

Installation in Practice

The beauty of roll formed products lies in their ease of installation. Columns and beams are erected first, purlins are attached, and roof or wall panels are laid in place. Fasteners, clips, and simple seaming equipment are all that is needed to complete the job. Accessories like gutters and flashing are installed last, ensuring weatherproof performance.

Final Thoughts

From homes to warehouses, cold roll forming machines provide the foundation, the covering, and even the finishing touches of the building envelope. They not only streamline the construction process but also deliver durable, cost-effective results. For developers, choosing the right combination of machines means faster construction timelines and higher-quality buildings.