Climate-Based Guide to Choosing the Best Standing Seam Roof Profile

28 May

Standing seam metal roofs have become a preferred roofing solution for both residential and commercial structures due to their sleek appearance and superior weather resistance. However, the effectiveness of a standing seam roof heavily depends on choosing the right panel profile for your specific environmental conditions. Factors like precipitation, temperature changes, wind exposure, and even air salinity must be taken into account before selecting a standing seam profile.

Types of Standing Seam Profiles

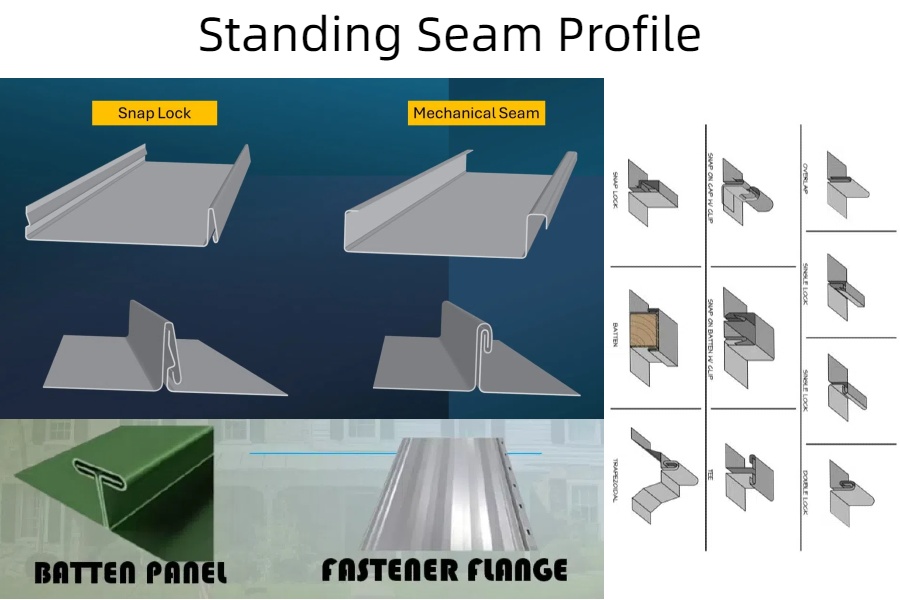

Standing seam roofing systems come in different forms, typically classified by their attachment and seam styles:

-

Snap-lock panels: Interlocking seams that do not require special tools.

-

Mechanical seam panels: Seams crimped with a seaming machine for stronger watertight connections.

-

Batten cap systems: Vertical seams formed by placing a cap over two adjacent panels.

-

Nail strip systems: Simplified installation without clips, suitable for smaller structures.

Each of these systems is suited for different climates and project requirements.

Cold and Snowy Regions

In regions with harsh winters, such as northern Europe or mountainous zones, snow accumulation and ice dams are major concerns. For these areas, mechanically seamed double-lock profiles are highly recommended. These profiles form the most watertight seam and can endure freezing temperatures and heavy snow without leakage.

Additionally, high-seam profiles (above 1 inch) offer extra protection against snow infiltration. Panel widths should be narrower to handle the load more efficiently, and snow guards can be installed easily with compatible standing seam designs.

High-Temperature and Coastal Areas

For warm, coastal climates such as southern China, Australia, or the southern U.S., the two main challenges are heat and salt-laden air. Snap-lock panels with hidden fasteners are ideal here, as they reduce potential corrosion points. Aluminum is often used in coastal environments due to its excellent corrosion resistance, and snap-lock systems pair well with this lightweight metal.

Thermal movement is another issue in hot climates. Snap-lock systems allow panels to expand and contract freely, preventing oil canning and other visual distortions. Proper use of clips and underlayment also enhances performance.

Wind-Exposed and Hurricane Zones

In hurricane-prone regions like the southeastern United States or island territories, buildings face extreme uplift pressures. For such environments, mechanical seam panels with continuous clips are essential. These profiles are engineered for high wind resistance and meet stringent codes like Miami-Dade or Florida Building Code approvals.

Using 180-degree seam locks creates a continuous seal that is far less likely to be compromised by flying debris or intense gusts. Extra anchoring and heavier gauge panels are often recommended in such areas for additional safety.

Dry Climates with Large Temperature Swings

Arid regions, such as parts of the southwestern U.S. or Middle Eastern deserts, experience rapid temperature shifts between day and night. These changes cause metal to expand and contract significantly. Floating clip systems paired with flexible profiles, such as nail strip or snap-lock, help accommodate this movement without damaging the roof system.

Choosing a reflective coating, such as a cool roof finish, also helps mitigate heat gain, reducing cooling costs and increasing indoor comfort.

Additional Considerations

Aside from climate, other important factors include:

-

Roof slope: Lower slopes may require mechanically seamed profiles to ensure water tightness.

-

Building use: Commercial buildings may prioritize durability and performance, while homeowners may also focus on aesthetics.

-

Installation complexity: Snap-lock systems are easier to install and more suitable for DIY or smaller projects.

Final Thoughts

A standing seam metal roof is a significant investment with the potential to last 40–70 years—provided the correct panel profile is selected. Climate-specific considerations are essential for ensuring the system performs as expected and stands the test of time. Whether you’re facing snow, salt, wind, or extreme heat, there’s a standing seam profile designed to handle those conditions. Always consult with a roofing professional to evaluate environmental factors, structural requirements, and aesthetic goals before making your final choice.