A Comprehensive Guide: Understanding C Purlins and Z Purlins

17 Feb

Understanding C Purlins and Z Purlins: A Comprehensive Guide

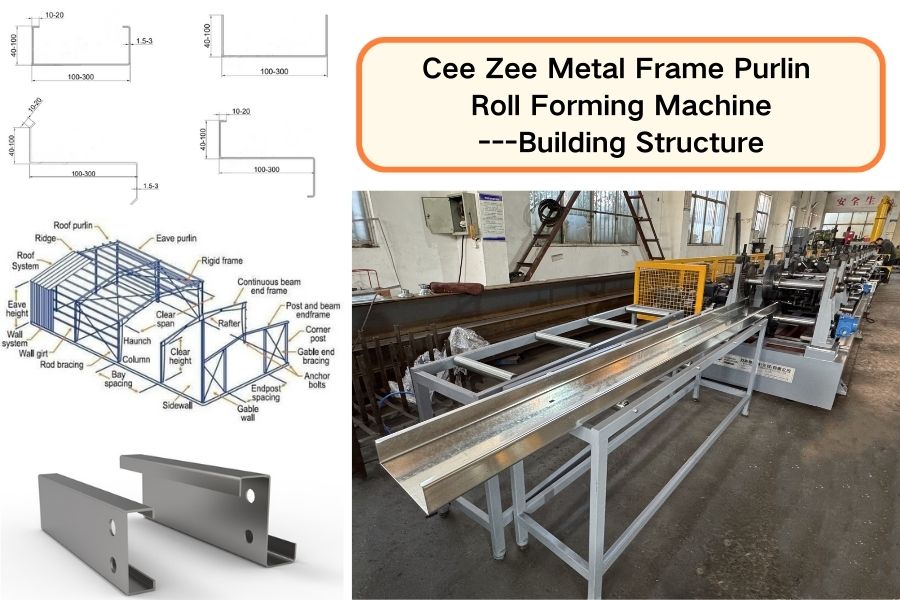

When it comes to structural support in construction, purlins play a crucial role. Among the most commonly used purlins are C purlins and Z purlins. These steel components are essential for providing stability and strength to roofs and walls in industrial, commercial, and even residential buildings. In this blog, we’ll explore the differences between C purlins and Z purlins, their applications, and why their thickness (ranging from 1.5mm-3.0mm, 1.5mm to 3.5mm) matters.

What Are C Purlins and Z Purlins?

C purlins and Z purlins are cold-formed steel sections shaped like the letters "C" and "Z," respectively. They are lightweight yet incredibly strong, making them ideal for supporting roofs and walls in various structures. Both types are made from high-quality steel and are often galvanized to prevent corrosion, ensuring durability even in harsh weather conditions.

C Purlins: These are shaped like the letter "C" and are primarily used for vertical support in walls and light roofing applications. They are easy to install and provide excellent load-bearing capacity.

Z Purlins: These are shaped like the letter "Z" and are commonly used in sloping roofs. Their unique shape allows them to overlap at the joints, providing greater structural integrity and flexibility.

Thickness Matters: 1.5mm to 3.5mm

The thickness of purlins is a critical factor in determining their strength and load-bearing capacity. Purlins typically range from 1.5mm to 3.5mm in thickness, depending on the application:

1.5mm to 2.0mm: Ideal for light-duty applications such as small sheds, garages, or residential projects where the load is minimal.

2.5mm to 3.5mm: Suitable for heavy-duty applications like industrial warehouses, commercial buildings, and large-span structures that require higher load-bearing capacity.

Choosing the right thickness ensures that the structure remains stable and safe while optimizing material usage and cost.

Applications of C Purlins and Z Purlins

Both C purlins and Z purlins are widely used in the construction industry due to their versatility and strength. Here are some common applications:

Roofing Systems: Z purlins are often used in sloping roofs due to their ability to overlap and provide continuous support. C purlins are used in lighter roofing systems.

Wall Framing: C purlins are commonly used in wall framing to provide vertical support and stability.

Industrial Sheds: Both types of purlins are used in the construction of industrial sheds, where durability and strength are paramount.

.png)

.png?x-oss-process=image/resize,w_100/quality,q_100)

Advantages of Using C Purlins and Z Purlins

Lightweight: Both C and Z purlins are lightweight, making them easy to transport and install.

Durable: Made from galvanized steel, they are resistant to rust and corrosion.

Cost-Effective: Their lightweight nature reduces transportation and installation costs.

Versatile: Suitable for a wide range of applications, from residential to industrial projects.

Conclusion

C purlins and Z purlins are indispensable components in modern construction. Their unique shapes, combined with the ability to choose the right thickness (1.5mm to 3.5mm), make them suitable for various applications. Whether you’re building a small garage or a large industrial warehouse, understanding the differences between these purlins will help you make the right choice for your project.

If you are interested in the C Z Purlin Roll Forming Machine, welcome to inquiry!